Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

A technical breakdown of the DINOSAW 7-axis robotic stone carving cell. Explore its architecture, core components, operational parameters, and failure mitigation for granite, marble, and limestone. Achieves ±0.06 mm repeatability.

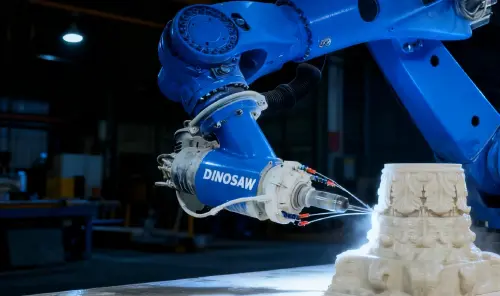

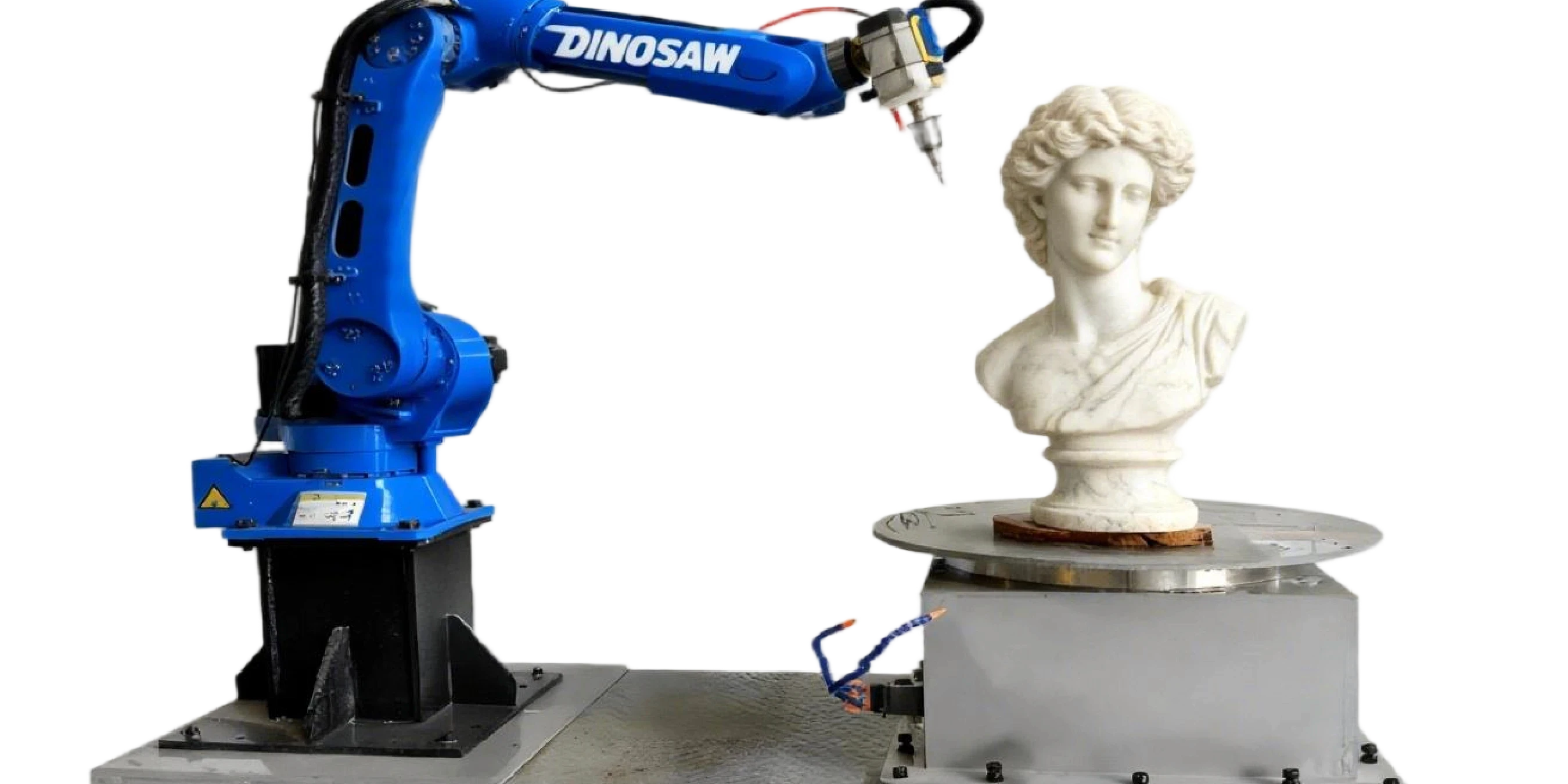

Stone carving in granite, marble, and limestone pushes mechanical limits—precision, rigidity, and dust/slurry control. A 7-axis robotic stone carving cell (6-axis robot + rotary table + water-cooled spindle) delivers repeatability (±0.06 mm, manufacturer-reported), safer operations, and predictable cycle times.

See the Dinosaw robotic stone carving for the reference architecture powered by diamond tools.

Need to match these technical specs to your production floor? Our engineers can provide a detailed integration plan.

System Architecture: A Four-Pillar Integration for Robotic Stone Processing

The cell's performance is built on the seamless interaction of four pillars: mechanics, controls, software, and safety. A typical workflow starts with a 3D scan or CAD model, which is imported into the CAM software to generate a multi-axis toolpath. This program is then sent to the robot controller, which executes the complex, synchronized movements required for carving.

- Mechanical Pillar: Comprises the industrial robot, the rotary table, the spindle, and the endeffector tooling. The structure is designed for maximum stiffness to counteract the cutting forces and vibrations inherent in stone processing. An automatic tool changer (ATC) system can be integrated to allow for unattended operation from roughing to finishing.

- Controls Pillar: A real-time industrial controller acts as the system's brain, synchronizing the motion of all seven axes with microsecond precision. It manages I/O signals from sensors, communicates with the spindle drive, and executes safety logic.

- Software Pillar: OLP/CAM software is the interface between human intent and machine execution. It allows for complex toolpath generation, collision detection, and cycle time estimation in a virtual environment, maximizing machine uptime.

- Safety & Environmental Pillar: A physical enclosure with interlocked doors, IP-rated component protection (e.g., IP65), and integrated dust/slurry management systems ensure operator safety and machine longevity. This includes provide high-volume airflow per dust system specification, \(m^{3}/h\) and directed coolant flow for wet carving.

Core Components: Parameters and Operating Ranges

Each component within the stone robot cell has a defined operating range. Understanding these parameters—from the water-cooled spindle for carving system to the specific DINOSAW diamond tooling—is crucial for process optimization and troubleshooting.

| Component | Key Parameters & Typical Ranges |

|---|---|

| Water-Cooled Spindle | Speed: 6,000–24,000 RPM; Torque: Nm at various RPMs; Coolant Flow: 5–15 L/min (1.3–4.0 gpm) |

| DINOSAW Diamond Tools | Shank Sizes: 6 mm, 8 mm, 12 mm ; Tool Families: Ball-nose/flat-end mills, tapered engraving bits, V-groove bits, burrs. |

| Rotary Table (7th Axis) | Diameter: diameter matched to max block size (confirm during fixture design), mm/in; Max Load: load capacity selected to your heaviest block (confirm during mechanical design), kg. |

| Vision/Scanning System | Resolution: Scanner resolution varies by model (confirm with vendor), mm point spacing. |

Common Failure Modes & Mitigation Strategies

Proactive maintenance and an understanding of failure modes are essential for maximizing uptime in a high-wear stone carving environment.

Failure: Vibration & Chatter

- Signal: Visible chatter marks on the workpiece surface, poor edge quality.

- Mitigation: Increase system rigidity (check fixture clamping), adjust spindle RPM to move out of a resonant frequency, reduce step-over or depth-of-cut, and inspect for tool wear or imbalance.

Failure: Dust & Slurry Ingress

- Signal: Premature bearing failure, encoder faults, stiff joint movement.

- Mitigation: Maintain positive air pressure within the robot's protective suit, regularly inspect seals and bellows, and ensure the dust extraction system is functioning at its specified airflow.

Failure: Spindle Thermal Drift

- Signal: Gradual loss of dimensional accuracy over a long carving cycle.

- Mitigation: Ensure the water-cooling circuit has adequate flow rate and temperature control. Implement a spindle warm-up cycle before critical finishing passes.

Failure: Cable Fatigue

- Signal: Intermittent I/O errors, axis drive faults.

- Mitigation: Use high-flex-life cables routed with correct bend radii. Regularly inspect the dress pack for signs of abrasion or snagging. Program robot movements to minimize excessive twisting of the final axes.

System Compatibility & Integration

A robotic cell does not operate in isolation. Its ability to communicate with other factory systems and accept standard data formats is key to its utility.

- PLC & Network Protocols: The robot controller can typically interface with master PLCs via industrial protocols like Profinet or OPC UA; confirm compatibility during design.

- CAM/OLP & Data Formats: Compatibility with industry-standard CAM software (e.g., SprutCAM, Robotmaster) is essential. The system should accept common 3D model formats (STEP, IGES) and post-process toolpaths into the robot's native language.

- Fixtures & I/O: The system provides configurable digital/analog I/O for controlling pneumatic or hydraulic fixtures, sensors, and other peripheral devices.

Baseline Starting Parameters for Stone Carving

The following tables provide conservative starting points for carving different types of stone. These must be refined based on the specific machine, tool, and material batch.

Granite (Hard, Abrasive)

| Process | Tool | Spindle Speed (RPM) | Feed Rate (mm/min) | Step-Over |

|---|---|---|---|---|

| Roughing | DINOSAW Ball-Nose Mill | 8,000–12,000 | 1,000–2,000 | 40-50% of tool diameter |

| Finishing/Lettering | DINOSAW V-Groove Bit | 15,000–20,000 | 500–1,000 | N/A |

Marble (Medium Hard, Less Abrasive)

| Process | Tool | Spindle Speed (RPM) | Feed Rate (mm/min) | Step-Over |

|---|---|---|---|---|

| Roughing | DINOSAW Ball-Nose Mill | 10,000–15,000 | 1,500–3,000 | 50-60% of tool diameter |

| Finishing | DINOSAW Tapered Bit | 18,000–24,000 | 800–1,500 | 5-10% of tool diameter |

Limestone/Sandstone (Softer, More Friable)

| Process | Tool | Spindle Speed (RPM) | Feed Rate (mm/min) | Step-Over |

|---|---|---|---|---|

| Roughing | DINOSAW Ball-Nose Mill | 12,000–18,000 | 2,500–4,000 | 50-70% of tool diameter |

| Finishing | DINOSAW Tapered Bit | 20,000–24,000 | 1,200–2,000 | 10-15% of tool diameter |

Safety, Compliance, and Summary

Safety & Compliance for Technical Operations

- Dust & Slurry Management: Ensure the cell's dust extraction system meets or exceeds local regulations for silica dust (e.g., OSHA in the US). For wet carving, slurry must be collected, filtered, and disposed of according to environmental laws.

- Operator PPE: Mandate the use of appropriate Personal Protective Equipment, including standards-compliant respirators, safety glasses, and hearing protection, even with an enclosed cell.

- IP Rating & Enclosures: Regularly inspect the integrity of IP-rated enclosures (e.g., IP65) and cable dress packs to prevent ingress that could lead to electrical shorts or mechanical failure. Safety interlocks on all access doors must be functional at all times.

Summary & Next Steps

The DINOSAW 7-axis carving cell is an engineered ecosystem designed for precision and durability in stone fabrication. Its architecture—from the water-cooled spindle and DINOSAW diamond tools to the robust control system—directly mitigates common failures like vibration chatter and thermal drift. For engineers and maintenance teams, this translates to higher uptime, consistent quality, and a safer work environment. The next step is to map these technical capabilities to your specific operational needs.

FAQs — Technical Specs & Integration

What robot payload and reach should I plan for?

A payload of load capacity selected to your heaviest block (confirm during mechanical design), kg and reach of reach sized to your largest part envelope (confirm during layout), mm/in are typical starting points. This must account for the weight of the spindle, tool changer, and the tool itself. The rotary table will have dimensions of diameter matched to max block size (confirm during fixture design), mm/in.

Rotary table capacity and indexing accuracy?

Plan for a table diameter matched to max block size (confirm during fixture design), mm/in with a max load capacity selected to your heaviest block (confirm during mechanical design), kg. Indexing accuracy is typically specified in arc-seconds (confirm with vendor). Ensure sufficient clearance around the table for the robot's full range of motion.

Managing thermal drift over long jobs?

Manage spindle temperature per manufacturer guidance (cooling and temperature control). Consider a warm-up cycle and schedule critical finishing passes after thermal stabilization.

Which PLC/network protocols are supported?

The system typically supports industrial protocols like Profinet or OPC UA for integration. Confirm specific protocol needs during the design phase. This allows for I/O mapping for peripherals (fixtures, sensors) and integration into a central safety circuit.

Mandatory safety signals and interlocks?

Typical safety practices include an emergency-stop circuit and interlocked access doors, complemented by enclosure protection (e.g., IP65) and spindle status monitoring. Consult local standards for required devices and test cadence.

In-line tool wear detection approaches?

Common methods include monitoring spindle load trends for increases, using software-based tool life counters to trigger a change, or integrating a laser tool-setter to automatically measure tool dimensions between cycles.

Do I need OLP and scan-to-toolpath?

Yes. Offline Programming (OLP) software (e.g., SprutCAM) is essential for maximizing uptime, as it allows programming while the machine runs. It is also critical for simulating complex 7-axis moves to avoid collisions and converting 3D scan data into executable toolpaths.

English

English 中文

中文