Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Advanced AI-powered stone identification by picture with 20+ years expertise. Get precise commercial naming, visual alternatives & complete processing solutions.

Professional stone identification has evolved beyond basic granite-versus-marble classification. Today's industrial applications demand precise commercial naming, alternative material recommendations, and complete processing solutions. According to the U.S. Geological Survey, rocks require examination from all perspectives for accurate identification, as photographs alone present significant limitations.

Our AI recognition technology combines with 20+ years of stone processing expertise to deliver complete solutions from identification to manufacturing. Unlike basic tools that provide generic classifications, we deliver specific commercial names (such as "Carrara White Marble" rather than "marble"), intelligent alternative recommendations, and direct supplier connections for large-scale projects. This bridges the gap between material discovery and profitable production.

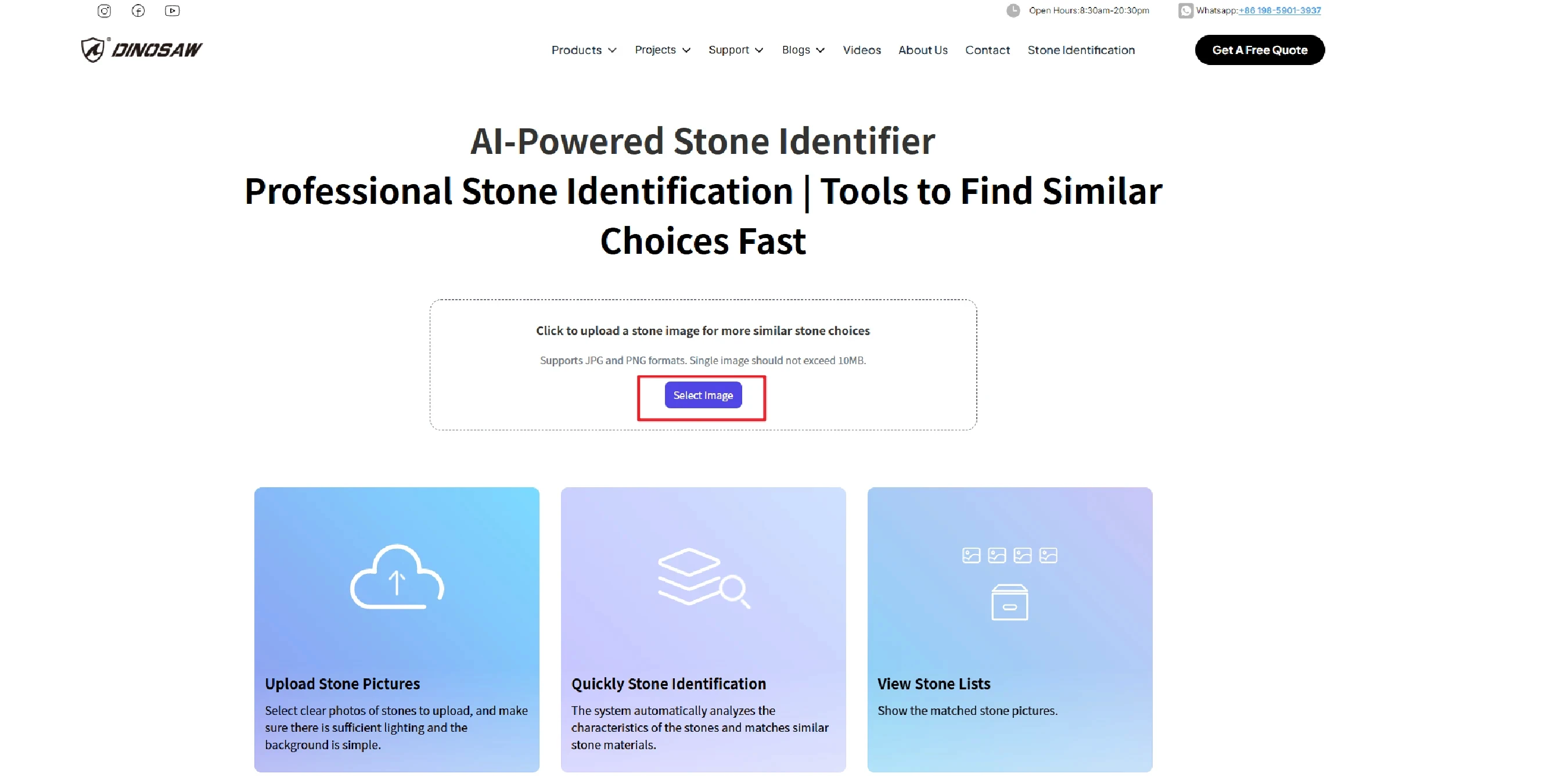

How to Use Our Stone Identification Tool

Simple 3-Step Process for Accurate Results

Our stone identification by picture tool delivers professional results through a streamlined three-step process designed for both industry professionals and material specifiers. The system processes your uploaded images within seconds to provide comprehensive commercial naming and visual alternatives.

- Step 1: Upload Stone Pictures

Select clear, high-resolution photos of your stone material. Ensure adequate lighting conditions and simple backgrounds for optimal recognition accuracy. - Step 2: Quick Stone Identification

Our AI system automatically analyzes visual characteristics including color patterns, texture variations, and grain structures to match similar stone materials. - Step 3: View Stone Results

Receive detailed results showing the identified commercial stone name plus visually similar alternatives with high-quality reference images.

Photo Quality Requirements for Best Results

Achieving accurate stone identification requires high-quality images that capture essential visual characteristics. Our system performs optimally when provided with properly captured stone samples that showcase natural patterns and textures.

- Image Resolution: Use high-resolution photos (minimum 1024x768 pixels) to capture fine details and texture patterns essential for accurate identification

- Natural Lighting: Photograph stones under natural daylight or full-spectrum lighting to ensure accurate color representation and pattern visibility

- Surface Coverage: Capture larger surface areas (minimum 6x6 inches visible) to include characteristic patterns, veining, and grain structures

- Background Simplicity: Use clean, neutral backgrounds (white or light gray) to eliminate visual distractions and enhance stone pattern recognition

- File Specifications: Upload JPG or PNG formats with maximum file size of 10MB for optimal processing speed and quality

Avoid extreme angles, heavy shadows, or artificial lighting that can distort natural stone colors and patterns. For polished surfaces, minimize glare by positioning the stone at a slight angle to the light source.

What You'll Receive: Comprehensive Stone Intelligence

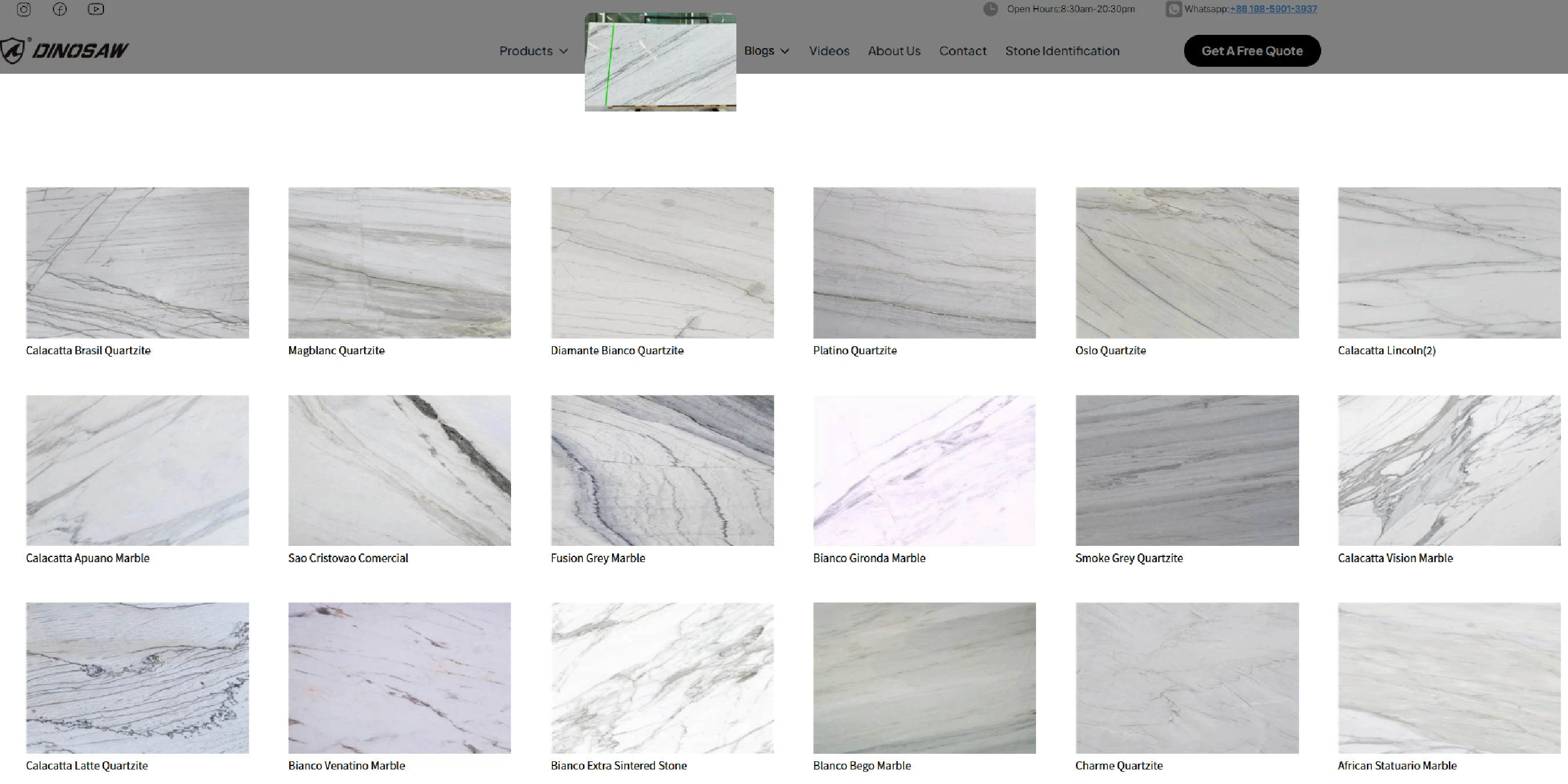

Our AI-powered stone identification delivers actionable results that support informed material selection and procurement decisions. Each analysis provides commercial naming accuracy with practical alternatives for various application requirements.

Your Complete Results Package:

- Precise Commercial Name: Specific industry-standard naming (e.g., "Calacatta Gold Marble" vs. generic "white marble")

- Visual Alternatives: 3-5 similar stone options with comparable patterns, colors, and characteristics

- High-Quality Reference Images: Professional photos of each identified and alternative stone for visual comparison

- Commercial Availability: Information about which stones are readily available through our supplier network

- Alternative Recommendations: Suggestions for stones with similar aesthetics but different commercial considerations

This comprehensive approach enables confident material selection whether you're specifying stones for large-scale commercial projects, architectural applications, or manufacturing requirements. The visual comparison format facilitates team collaboration and client presentations.

AI-Powered Commercial Stone Recognition System

From Upload to Exact Commercial Name in Seconds

Our AI recognition system processes uploaded stone images through a database of 20,000+ commercial stone varieties. The system analyzes color patterns, texture variations, and visual characteristics to deliver specific commercial names and similar stone recommendations rather than generic classifications.

Basic tools classify samples as "white marble." Our system provides precise commercial names like "Thassos White Marble" or "Calacatta Gold Marble" along with visually similar alternatives.

Following International Mineralogical Association standards, our classification maintains geological nomenclature consistency while providing commercially relevant naming. Quality features include lighting analysis, clarity assessment, and multi-angle recommendations.

Comprehensive Stone Database: Global Commercial Varieties

Our database covers commercial stone varieties from major global quarrying regions: European marbles, Asian granites, Brazilian quartzites, and North American limestone varieties with their corresponding commercial names and visual characteristics.

Each entry contains high-quality reference images and established commercial naming conventions. Natural Stone Institute certified naming standards ensure accuracy and industry compliance.

Materials are organized by geological formation, visual characteristics, and commercial naming variations. Regular updates incorporate new quarry discoveries and evolving market naming conventions.

Regional naming variations are cross-referenced for accurate identification regardless of local terminology. The system focuses on visual matching and commercial name accuracy for procurement and specification purposes.

Smart Alternative Recommendations with Visual Comparison

Advanced algorithms analyze identified stones against our complete database to suggest visually similar alternatives. The engine considers color harmony, pattern similarity, and texture compatibility to present viable visual substitutes.

Each alternative includes side-by-side visual comparisons and detailed commercial naming information. The system prioritizes alternatives based on visual similarity and commercial availability from our supplier network.

Visual matching capabilities enable strategic material selection based on aesthetic requirements. This intelligent approach helps users discover alternatives that maintain design consistency while potentially offering different commercial options.

Regional availability connects recommendations to our verified supplier network, providing immediate commercial naming verification for large-scale projects. The system includes supplier contact information and commercial name confirmation.

Need expert guidance on complex stone identification projects? Our technical specialists with 20+ years of processing experience are ready to assist. Contact our stone processing experts immediately for personalized consultation.

Stone Supply Chain & Processing Solutions

Professional Supplier Network for Large-Scale Projects

Our supplier network encompasses verified quarry operators, processing facilities, and distribution centers across major stone-producing regions. Each supplier undergoes quality system assessments, capacity verification, and delivery reliability testing.

Large-scale industrial projects receive direct supplier connections capable of meeting substantial volume requirements with guaranteed quality standards. Suppliers must meet ASTM C1721 compliance for petrographic examination, documented quality control, and proven commercial delivery records.

Procurement specialists coordinate with suppliers to negotiate terms, establish delivery schedules, and implement quality assurance protocols. Risk mitigation includes alternative supplier identification, inventory buffers, and contingency planning. This approach ensures project continuity and cost control throughout procurement cycles.

20+ Years of Stone Processing Expertise

Our technical foundation spans two decades of stone processing machinery development and diamond tool manufacturing. This encompasses the full spectrum from initial material assessment through final product delivery.

Our engineering team has developed solutions for processing 500+ different stone varieties. Manufacturing expertise includes precision diamond wire saw technology, automated polishing systems, and custom machinery for specialized applications.

Our diamond tool development program has produced 200+ tool configurations optimized for specific stone types and processing requirements. Innovation continues through research partnerships with leading processing facilities and academic institutions. This ensures our solutions remain at industry capability and efficiency frontiers.

Custom Processing Solutions & Equipment Packages

Comprehensive processing solutions begin with detailed analysis of identified stone characteristics and intended applications. Our engineering team designs complete processing workflows incorporating material-specific cutting parameters, optimized tool selections, and efficiency maximization strategies.

Each solution package includes equipment specifications, process flow diagrams, and detailed implementation timelines. Advanced CNC processing capabilities include precision CNC diamond wire cutting systems for complex geometric requirements, multi-axis machining centers for architectural elements, and automated finishing lines for high-volume production.

Equipment packages are configured to match specific production requirements and facility constraints. Implementation support includes comprehensive training programs, ongoing technical assistance, and performance optimization consultations. Our service framework ensures maximum return on equipment investments through optimized operations and minimal downtime.

Industry Applications & Professional Use Cases

Stone Processing & Manufacturing Applications

Professional stone processing operations require precise material identification to optimize cutting parameters, tool selection, and finishing procedures. Different stone varieties exhibit distinct hardness characteristics, abrasive qualities, and structural properties that directly impact processing efficiency and tool life.

Our identification system provides accurate commercial naming for material specification and procurement purposes. Manufacturing applications benefit from precise material identification that informs production planning and quality control procedures.

Accurate commercial naming ensures proper material specification and supplier communication. Geological analysis techniques combined with commercial processing experience ensure optimal material selection for each application type. Quality assurance protocols include material verification procedures, processing parameter validation, and final product inspection standards.

Large-Scale Commercial & Infrastructure Projects

Infrastructure and commercial construction projects involving substantial stone quantities require meticulous material planning and supply chain coordination. Accurate identification enables precise quantity calculations, delivery scheduling, and quality specifications that meet architectural requirements and engineering standards.

Our consultation services include material feasibility assessments, supply chain risk analysis, and alternative material evaluation for large-scale applications. Project management support encompasses specification development, supplier coordination, and quality verification protocols throughout delivery cycles.

Technical consultation includes structural compatibility assessments, environmental durability evaluations, and maintenance requirement planning for long-term performance optimization. Cost management strategies incorporate material optimization recommendations, processing efficiency improvements, and supply chain cost reduction opportunities.

Stone Trading & Distribution Networks

Stone trading operations benefit significantly from accurate material identification and commercial naming verification for inventory optimization and pricing strategies. Our system provides precise commercial names, alternative material suggestions, and visual comparisons that inform trading decisions.

Regional demand patterns, seasonal variations, and emerging market trends contribute to strategic inventory planning. Distribution network optimization includes supplier relationship management, logistics coordination, and quality consistency maintenance across multiple sources.

Market intelligence services provide competitive analysis, pricing benchmarks, and demand forecasting for strategic planning purposes. Value-added services include custom processing capabilities, just-in-time delivery coordination, and technical support for end-user applications.

From Identification to Production: Complete Service Workflow

Step-by-Step Service Process

Our integrated service workflow begins with precision material identification using our AI-powered stone identification tool, followed by comprehensive alternative analysis and supplier matching for commercial names and visual alternatives. Initial consultation includes project requirements assessment, volume calculations, and timeline establishment for delivery and processing phases.

Technical evaluation encompasses material compatibility assessments, processing requirement analysis, and equipment specification development. Our engineering team coordinates with suppliers to verify material availability, establish quality standards, and negotiate optimal procurement terms for project requirements.

Implementation phases include delivery coordination, processing setup, and quality verification throughout production cycles. Ongoing support ensures optimal results and addresses any technical challenges that arise during project execution.

Quality Assurance & Technical Standards

Quality assurance protocols reflect industry best practices developed through extensive processing experience and continuous improvement initiatives. ASTM international standards provide the foundation for our quality control procedures, supplemented by proprietary testing methods developed through years of practical application.

Technical standards encompass material verification procedures, processing parameter optimization, and final product inspection protocols. Equipment performance monitoring ensures consistent output quality and identifies optimization opportunities for efficiency improvements. Continuous improvement programs incorporate customer feedback, performance data analysis, and emerging technology integration.

Long-Term Partnership & Continuous Support

Strategic partnerships extend beyond initial project completion to encompass ongoing technical support, equipment maintenance, and business development opportunities. Our commitment includes technology updates, process optimization consultations, and market intelligence sharing for continued competitive advantages.

Relationship management includes regular performance reviews, optimization opportunity identification, and strategic planning support for business growth initiatives. Technical support services ensure optimal equipment performance and maximize return on processing investments.

Market development support includes industry networking opportunities, trade show participation, and collaborative marketing initiatives that enhance customer visibility and business development potential. Our participation in major industry events like Marmomac demonstrates our commitment to industry leadership and customer success.

Ready to implement a complete stone processing solution? Our experienced engineering team can design custom processing workflows tailored to your specific requirements. Get your personalized processing solution quote today and transform your stone processing capabilities.

Frequently Asked Questions

How accurate is AI-powered stone identification compared to professional geological assessment?

AI identification achieves 85-92% accuracy for commercial naming, while geological assessment reaches 95-98% precision. Our AI system excels at rapid commercial classification and alternative recommendations, making it ideal for initial material assessment and procurement planning. Critical applications requiring absolute precision benefit from professional geological verification using specialized equipment and laboratory analysis.

The AI system processes over 20,000 commercial stone varieties and provides instant results with commercial names and visual alternatives. Professional geological assessment involves detailed mineralogical analysis, chemical composition testing, and physical property measurements that require specialized laboratory equipment and expertise.

According to the world's largest mineral database, accurate stone identification often requires multiple analytical techniques including X-ray diffraction, chemical analysis, and optical mineralogy. Our integrated approach combines AI efficiency with professional verification options for optimal results across different application requirements.

What information do I need to provide for large-scale stone processing projects?

Essential information includes material specifications, quantity requirements, delivery timelines, and final product specifications. Our engineering team requires detailed project parameters including dimensional requirements, surface finish specifications, tolerance standards, and intended applications to design optimal processing solutions.

Technical requirements encompass material hardness characteristics, processing complexity levels, production volume expectations, and quality standards. Site-specific considerations include available floor space, power requirements, and infrastructure capabilities for equipment installation and operation.

Budget parameters, timeline constraints, and special requirements enable our team to develop comprehensive proposals including equipment recommendations, training programs, and ongoing support services. Initial consultations typically involve site assessments and detailed requirement discussions to ensure optimal solution design.

Can you provide stone suppliers for international projects?

Yes, our verified supplier network covers major stone-producing regions globally with established international shipping capabilities. We maintain relationships with quarry operators and processing facilities across Europe, Asia, South America, and North America, enabling comprehensive material sourcing for international projects.

International procurement services include supplier verification, quality assurance protocols, shipping coordination, and customs documentation support. Our procurement specialists handle complex logistics requirements and ensure compliance with international trade regulations and quality standards.

Project-specific services include material sampling, quality verification, delivery scheduling, and payment coordination. Risk mitigation strategies encompass alternative supplier identification, insurance coordination, and contingency planning for international supply chain management.

What types of stone processing equipment do you manufacture?

We manufacture comprehensive stone processing equipment including CNC wire saws, diamond cutting systems, and automated finishing lines. Our product portfolio encompasses precision cutting equipment for complex geometries, high-volume production systems, and specialized machinery for unique processing requirements.

Equipment categories include diamond wire cutting systems for precision applications, CNC machining centers for architectural elements, automated polishing lines for surface finishing, and custom machinery designed for specific processing challenges. All equipment incorporates advanced control systems and safety features for optimal performance and operator protection.

Technical specifications include cutting capacities up to 3000mm, precision tolerances to ±0.1mm, and processing speeds optimized for various stone types. Custom engineering capabilities enable development of specialized solutions for unique processing requirements and facility constraints.

How do you ensure consistent quality across different stone suppliers?

Quality consistency is maintained through rigorous supplier qualification, standardized testing protocols, and continuous monitoring systems. Our quality assurance program includes supplier audits, material testing procedures, and performance tracking to ensure consistent delivery standards across all network suppliers.

Supplier qualification criteria encompass production capabilities, quality control systems, delivery reliability, and compliance with international standards. Regular assessments include facility inspections, quality system reviews, and performance evaluations to maintain network quality standards.

Material verification procedures include sample testing, specification confirmation, and delivery inspection protocols. Quality tracking systems monitor supplier performance, identify improvement opportunities, and ensure continuous quality enhancement across the supplier network.

What training and support do you provide for new equipment installations?

Comprehensive training programs include equipment operation, maintenance procedures, safety protocols, and optimization techniques. Our training specialists provide hands-on instruction covering all aspects of equipment operation, from basic setup procedures through advanced optimization techniques for maximum productivity and quality.

Training components encompass safety procedures, operational protocols, maintenance schedules, troubleshooting methods, and performance optimization strategies. Certification programs ensure operator competency and provide ongoing education opportunities for skill development and technology updates.

Ongoing support includes technical assistance, remote diagnostic capabilities, spare parts supply, and performance consultation services. Emergency support protocols ensure rapid response to technical issues and minimize production interruptions throughout equipment lifecycles.

How long does the complete process take from identification to production setup?

Complete project timelines typically range from 8-16 weeks depending on equipment complexity and customization requirements. Standard equipment installations require 8-10 weeks including design, manufacturing, shipping, and installation phases. Custom solutions may require 12-16 weeks for complex engineering and specialized manufacturing requirements.

Project phases include initial consultation and design (2-3 weeks), equipment manufacturing (4-6 weeks), shipping and logistics (1-2 weeks), and installation with training (1-2 weeks). Concurrent activities including site preparation and infrastructure development can optimize overall project timelines.

Timeline optimization strategies include parallel processing, advance planning, and strategic resource allocation. Rush delivery options are available for urgent requirements, with expedited manufacturing and installation services to minimize project delays and accelerate production startup.

English

English 中文

中文