Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

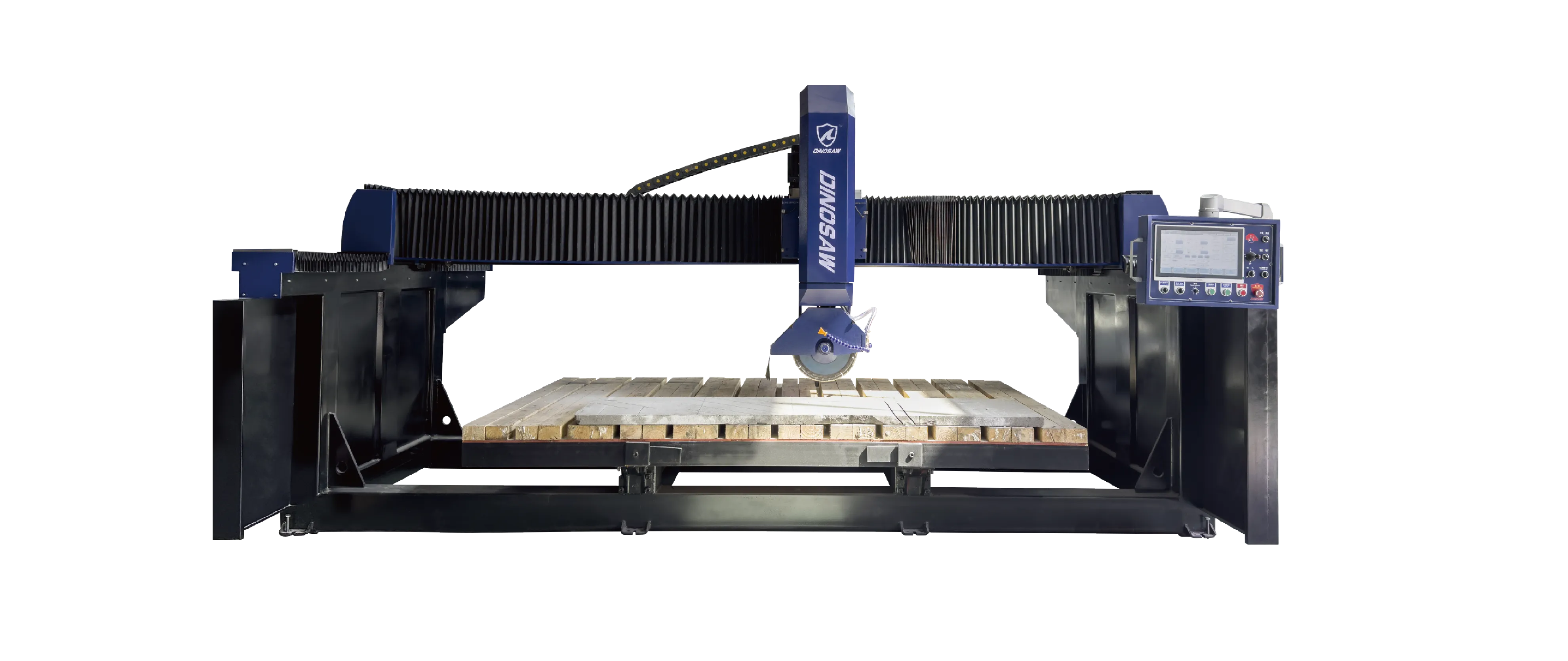

Explore the real CNC bridge saw price in 2025. Our guide covers TCO, ROI, and compares Asian vs. Euro/US models to help you make a profitable investment.

Investing in a CNC bridge saw represents one of the most critical financial decisions for any stone fabricator. This 2025 analysis reveals real market prices, hidden costs, and proven ROI strategies to help you make a profitable investment decision.

We'll break down costs across machine tiers, uncover the often-overlooked Total Cost of Ownership (TCO), and provide a practical Return on Investment (ROI) framework. Whether you're a startup or established factory, you'll find clear, data-driven insights to guide your decision.

Get a quote of CNC Bridge Saw NOW

Market Overview: What Should You Budget for a CNC Bridge Saw?

The global CNC bridge saw market divides into distinct tiers. Rather than confusing price lists, analyzing machines by origin and target customer segment provides clearer investment insights.

Tier 1: European & North American Brands (Premium Standard)

- Price Range: $85,000 - $350,000+

- Analysis: This tier includes industry leaders like Park Industries, Emmedue, and Veneto Technology. Your investment buys top-tier engineering, exceptional precision and stability, plus extensive local service networks. Pricing reflects significant R&D investment, brand value, and robust construction designed for decades of heavy industrial use.

Asian Machinery: The High Value-for-Money Champion

Asian machinery, particularly from top-tier Chinese manufacturers, represents exceptional value in today's global market. B2B website prices often serve as negotiation starting points and can mislead buyers. Based on actual market transactions, the real pricing is far more accessible.

Entry-Level 3/4-Axis Models

- Real Market Price: $18,000 - $30,000

- Analysis: This represents the sweet spot for startups and workshops with limited budgets. These machines handle standard countertop cutting, chamfering, and profiling with ease. They provide the fastest path to production automation without massive capital outlay.

Mainstream 5-Axis Models

- Real Market Price: $35,000 - $65,000

- Analysis: This represents the most competitive segment. For this investment, fabricators acquire full-featured 5-axis CNC bridge saws. At Dinosaw, we specialize in this tier, integrating high-quality, internationally recognized components-like Italian ESA control systems-into robust machine frames, delivering premium performance without premium pricing.

Why the Price Gap Exists

The significant price difference between tiers isn't arbitrary. It reflects fundamental differences in business models and manufacturing philosophies:

- R&D and Brand Equity: European/NA brands leverage decades of brand history and invest heavily in proprietary technology.

- Component Sourcing: While many Asian manufacturers use top-tier global components, labor and assembly costs remain lower.

- Service & Support: Western brands often maintain extensive, company-owned local service teams, with costs built into machine pricing.

- Resale Value: Premium brands typically maintain higher resale values over time.

7 Key Factors That Drive CNC Bridge Saw Pricing

Your final quote represents the sum of its parts. Understanding these components allows effective machine comparison and helps determine which features are essential for your operation.

Factor 1: The Axis Configuration (3-Axis vs. 4+1-Axis vs. True 5-Axis)

This represents the single biggest price driver:

- 3-Axis: Basic configuration moving in X, Y, and Z directions. Limited to vertical cuts only.

- 4+1-Axis: Adds tilting A-axis (typically for 45° miter cuts) and rotating C-axis. Axes can be positioned but cannot move simultaneously in complex tool paths.

- True 5-Axis: All five axes move simultaneously, enabling complex curved cuts, profiling, and shaping. This capability dramatically increases machine versatility and pricing.

For an in-depth comparison, see our Bridge Saw vs. 5-Axis CNC Saw: A Smart Investment Guide

Factor 2: Monoblock vs. Separate Wall Structure

The machine's foundation determines its stability and installation requirements:

- Monoblock: Built on a single, unified frame. Easier and cheaper to install, requiring no special concrete foundations. Standard for most modern shops.

- Separate Concrete/Steel Wall: Bridge rests on separate, precisely installed concrete or steel walls. Traditional design offers immense stability but requires significant, costly civil engineering work.

Factor 3: Control System & Software (The Machine's "Brain")

The CNC system dictates machine precision and ease of use. High-end Italian systems like ESA or OSAI are industry standards for reliability. While these premium systems increase initial cost, they deliver performance dividends.

Software represents another critical component. Many machine brands provide only basic software, forcing expensive separate purchases for powerful CAD/CAM packages like Alphacam or DDX EasySTONE. To eliminate this high cost for our customers, every Dinosaw bridge saw includes a fully licensed DDX EasySTONE version. As the exclusive agent for this leading Italian software in China, we provide world-class functionality out of the box.

Factor 4: Spindle & Motor Power (Performance Heart)

The spindle holds the blade, and its power determines cutting speed and capability. High-torque, Italian-made HSD spindles cost more than standard counterparts but deliver superior performance and longevity, especially when cutting dense materials like quartzite.

Factor 5: Worktable Features (Size, Tilting, Vacuum System)

Worktables must exceed your planned slab sizes. Features like hydraulic tilting (for easy slab loading) and integrated vacuum systems (for manipulating cut pieces) add significant cost but dramatically improve workflow efficiency.

Factor 6: Automation Features (Camera Systems, Tool Changing)

- Slab Camera: Integrated digital camera photographs slabs, allowing operators to digitally place templates and nest parts for maximum material yield. High ROI through waste reduction.

- Automatic Tool Changer (ATC): Found primarily on high-end machines combining sawing and routing, ATCs automatically switch between saw blades and milling tools, enabling unattended operation.

Factor 7: Brand Reputation and Manufacturing Origin

As discussed in market tiers, brand reputation and manufacturing location significantly influence pricing. The cost includes not just the physical machine but also quality assurance, reliability, and after-sales support associated with the brand.

For a deeper dive into all components, explore our Anatomy of a CNC Bridge Saw: An Expert's 2025 Guide

Beyond the Sticker Price: Understanding Total Cost of Ownership

The purchase price is just the beginning. Smart business owners calculate Total Cost of Ownership (TCO) over 3-5 years to understand the true financial impact of their investment.

One-Time Costs: Shipping, Installation, and Foundation

These unavoidable costs require careful budgeting:

- Shipping & Installation: Depending on location and machine origin, costs range 5-15% of machine price. Covers freight, insurance, rigging, and technician assembly/calibration time.

- Foundation: Monoblock saws need flat, reinforced concrete floors. Separate-wall saws require expensive custom foundations.

Recurring Costs: Tooling, Power, and Water

These represent your daily operational expenses:

- Tooling (Blades): Quality 16-inch diamond blades from Western suppliers cost $220-$400 per blade according to BladesDirect . This is where Dinosaw provides significant TCO advantages. Operating our own diamond tool factory, we supply high-performance, machine-matched saw blades directly to customers for less than half the price of typical European or American brands.

- Power Consumption: Large bridge saws are power-hungry machines. Account for monthly electricity costs based on kilowatt rating and operating hours.

- Water Recycling: Proper water treatment and recycling systems are essential for stone fabrication, saving on water bills while meeting environmental requirements.

Long-Term Costs: Maintenance and Software

- Maintenance: Annual Maintenance Contracts (AMC) typically cost 3-8% of machine value yearly. While expensive, they prevent costly downtime through regular preventative care. Learn more in our Bridge Saw Maintenance Guide .

- Software Subscriptions: Many brands charge recurring software subscriptions exceeding $1,200 annually per seat, as shown by Autodesk pricing . Dinosaw bridge saws eliminate this recurring cost entirely. Each machine includes a full, perpetual license of powerful DDX EasySTONE software.

Is It Worth It? A Practical ROI Calculation Guide

A CNC bridge saw doesn't cost money—it makes money. Calculating Return on Investment (ROI) proves its value. Global demand for processed stone remains strong, with Markets forecasting continued growth , making this a prime time for efficiency investments.

Revenue Boost: Unlocking High-Profit Jobs

A 5-axis bridge saw unlocks capabilities commanding premium prices:

- Miter Edges: Creating waterfall islands and thick-profile countertops becomes fast and precise.

- Sink Cutouts & Curves: Complex sink cutouts, curved bar tops, and custom shapes are impossible with manual saws but easy for 5-axis machines.

- Increased Throughput: CNC saws cut faster and more accurately than manual methods, allowing more jobs per week.

Cost Savings: Reduced Labor and Minimized Waste

- Labor: One skilled operator runs a CNC saw, whereas manual fabrication might require two or three people for equivalent output. This addresses ongoing skilled labor shortages, a key issue highlighted by the Natural Stone Institute .

- Material: Camera and software systems enable digital nesting of parts on virtual slabs. This maximizes material yield and drastically reduces expensive stone waste.

Smart Investment Strategies: New vs. Used vs. Financing

How you pay for the machine is as important as which one you choose.

The Pros and Cons of Buying Used CNC Bridge Saws

Buying used can save 30-50% on initial price. However, it comes with risks: no warranty, potential hidden mechanical issues, and outdated technology. Used machines may lack compatibility with latest software or efficiency to compete with modern shops.

How Financing Makes New Machines Affordable

Financing spreads machine costs over several years, making monthly payments manageable while preserving cash flow for operational needs. Government-backed programs, such as those from the U.S. Small Business Administration , provide favorable equipment purchase terms, making new machines more accessible than you might think.

Your Next Step: Get a Custom Quote for Your Factory

Choosing the right CNC bridge saw shapes your business for years to come. By looking beyond initial pricing and analyzing Total Cost of Ownership and Return on Investment, you can invest with confidence. The key is finding the right balance of technology, performance, and affordability matching your specific production needs.

From high-value Asian machines with premium components to top-tier European workhorses, the perfect solution for your factory exists.

Ready to calculate exact pricing and ROI for your specific needs? Send us your requirements on WhatsApp for a free, no-obligation quote today

Frequently Asked Questions

How much does a basic CNC machine for granite cost?

A basic, new CNC machine for granite, typically a 3-axis or 4+1-axis bridge saw from a quality Asian manufacturer, costs between $18,000 and $30,000. This price point provides essential capabilities for cutting and mitering standard countertops. Final cost depends on brand, worktable size, and included software.

Is a 5-axis CNC bridge saw worth the extra cost?

Yes, for most growing fabrication shops, a 5-axis CNC is worth the extra investment. It unlocks high-profit capabilities like complex miter cuts for waterfall islands, sink opening cuts, and curved shape creation. This versatility enables more complex, higher-margin jobs, leading to faster ROI, typically within 12-24 months.

What is the average lifespan of a CNC bridge saw?

The average lifespan of a well-maintained CNC bridge saw is 10 to 20 years. Longevity heavily depends on build quality, operating environment, and adherence to strict preventative maintenance schedules. Premium European machines may last longer, while proper care can significantly extend any machine's life.

Can I cut materials other than stone with a bridge saw?

While designed primarily for natural and engineered stone like granite, marble, and quartz, some CNC bridge saws can cut other hard materials. With correct blades and cutting parameters, they can process sintered stone (like Dekton), porcelain slabs, and even concrete. Always consult manufacturer specifications before cutting non-standard materials.

What are the main hidden costs when buying a CNC bridge saw?

Main hidden costs are Total Cost of Ownership (TCO) items:

- Shipping & Installation: 5-15% of machine cost

- Tooling: Constant blade expenses (Dinosaw mitigates this with factory-direct blades at half the price of Western brands)

- Software: Often recurring subscriptions (Dinosaw eliminates this with perpetual DDX EasySTONE licenses)

- Utilities: Increased electricity and water consumption

- Maintenance: Annual service contracts (3-8% of initial investment)

How much space do I need to install a monoblock bridge saw?

You generally need floor space of approximately 25 ft × 20 ft (7.5m × 6m) for a standard monoblock bridge saw. This provides enough room for the machine's full range of motion and safe working space for operators to load and unload slabs. Always refer to specific machine technical footprints provided by manufacturers.

Do I need a highly skilled operator for a modern CNC bridge saw?

Modern CNC bridge saws are much easier to operate thanks to user-friendly software. You need a tech-savvy operator who's a good problem-solver, but they don't need to be traditional, master-level stone masons. Good training programs, like those provided by Dinosaw, typically get competent employees operating machines efficiently within one to two weeks.

English

English 中文

中文