Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Is an automated polishing line the right upgrade for your factory? Our 2025 guide covers ROI, pre-investment checklists, and key features to help you decide.

When stone fabrication demand grows, the polishing stage becomes your biggest bottleneck. Bridge polishers cap daily output and create inconsistencies, while skilled labor gets harder to find every year. If missed deadlines are becoming the norm, you're facing a decision that will shape your factory's future.

An automated polishing line isn't just another machine-it's a complete shift to continuous, industrial-scale workflow. This guide provides the decision-making framework to determine if this significant capital investment can unlock your factory's true potential through dramatic throughput increases and flawless quality.

The Core Difference: Automated Line vs. Bridge Polisher

Understanding the value starts with recognizing the fundamental shift. Think craftsman's workshop versus modern manufacturing plant.

Workflow & Throughput: From One-Slab-at-a-Time to Continuous Flow

A bridge polisher handles one slab at a time in a fixed position. The process stops and starts: polish one slab, remove it, load the next one.

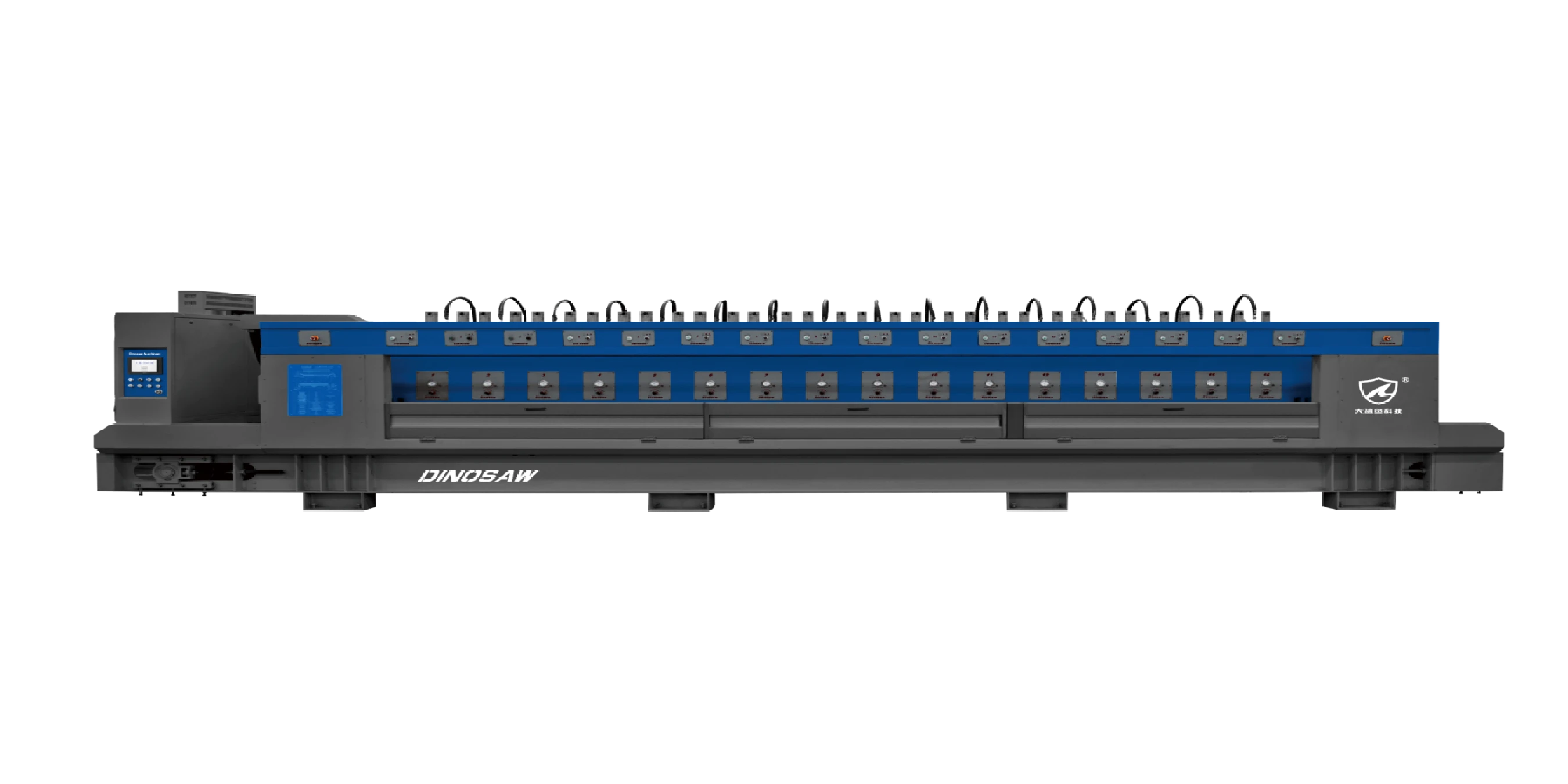

An automated polishing line transforms this into continuous flow. Slabs move on a conveyor belt through 12 to 20+ polishing heads, each equipped with progressively finer abrasives. By the time a slab exits the line, it's completely polished, dried, and ready for the next stage.

This industrial approach keeps the system constantly working. A well-run line processes over 1,000 square meters daily , nearly ten times more than manual or semi-automatic methods.

Consistency & Quality Control: The End of Human Error

Even skilled operators produce slight variations between slabs or across large surfaces. An automated line eliminates this variable completely.

Each polishing head applies precise, computer-controlled pressure for set durations. Every square inch of every slab receives identical treatment. This mechanical precision guarantees uniform gloss and finish meeting the strictest industry benchmarks, like quality levels defined by the Natural Stone Institute standards.

For businesses serving high-end architectural projects or large commercial contracts, this guaranteed consistency becomes a powerful competitive advantage.

Labor Requirements: Shifting from Skilled Operator to Line Supervisor

A bridge polisher demands skilled operators with deep understanding of stone properties and polishing techniques. An automated line changes the game entirely.

Artisanal skill gets replaced by trained supervision - managing line settings, overseeing workflow, performing routine checks. This addresses the persistent skilled labor shortage highlighted by industry publications like Stone World.

Your most experienced personnel can focus on higher-value tasks: quality control, custom fabrication, and complex projects that actually require human expertise.

The Business Case: Is an Automated Polishing Line a Smart Investment?

An automated line isn't an expense - it's an investment in capacity and efficiency. While detailed Total Cost of Ownership (TCO) analysis depends on specific variables, you can build a compelling business case by focusing on the right metrics.

A Framework for Analyzing Your Payback Period

Rather than generic calculators, we provide a framework for analyzing potential returns specific to your business. This approach empowers data-driven decisions.

1. Calculate Your Potential Revenue Increase:

- Current Max Daily Output (in m²) × Average Selling Price per m² = Current Max Daily Revenue

- Projected Line Output (e.g., 800 m²) × Average Selling Price per m² = Projected Max Daily Revenue

The difference represents your gross revenue potential.

2. Estimate Your Increased Operational Costs:

- Monthly Equipment Financing/Lease Cost: Primary new fixed cost

- Increased Energy Consumption: Based on kW rating and operating hours

- Consumables (Abrasives): Cost of abrasive segments per square meter polished

- Scheduled Maintenance: Lubricants, parts, and technician time

3. Analyze the Net Impact:

Subtract increased operational costs from potential revenue increase to project net financial gain. This reveals realistic payback periods and profitability impact. Accelerating demand for finished stone products, as shown in the Grand View Research report supports scalable production models.

Beyond Speed: How Consistent Quality Reduces Re-work and Boosts Reputation

Financial benefits extend beyond raw output. Automated lines drastically reduce re-work and rejected slabs due to quality issues.

Every slab failing final inspection represents lost material, labor, and time. Ensuring consistently perfect finishes directly reduces this waste, improving net profit margins on every job. What's more, a reputation for flawless, consistent quality allows confident bidding on larger, more lucrative projects demanding stringent quality control.

Feeling overwhelmed by the numbers? Let our experts help you build a personalized ROI calculation for your factory.

Chat with us on WhatsApp for a free consultation

Are You Ready? A Pre-Investment Checklist for Your Factory

Successful upgrades require more than purchasing the machine. Your factory must be prepared for integration. Here's your readiness checklist.

Physical Plant Requirements: Space, Foundation, and Power Supply

- Footprint: Complete polishing lines often exceed 20-30 meters (65-100 feet) in length. Do you have uninterrupted floor space available?

- Foundation: Immense weight and operational forces require reinforced concrete foundations of specific thickness and strength. Standard factory floors may be insufficient.

- Power & Utilities: Significant power requirements demand confirmation your electrical service can handle the load. Additionally, reliable compressed air and water supplies are essential.

Workforce Readiness: Training Your Team for a New Era

Your team transitions from manual skills to system management. This involves training on control software, understanding diagnostics, and learning procedures for changing abrasives and performing daily maintenance.

Investing in manufacturer-led training is crucial for smooth, efficient startup. This aligns with industrial machinery best practices outlined by organizations like the VDMA (German Engineering Federation) , which emphasize proper operator training for safety and efficiency.

Financial Health: Securing Capital for a Major Investment

This represents significant capital expenditure. Before engaging manufacturers, establish a clear financial plan including securing financing, understanding terms, and budgeting beyond just the machine - shipping, installation, and potential facility upgrades matter too.

Many principles in our CNC Investment Guide: 10 Golden Rules apply directly to this process.

Key Features to Consider in a Modern Stone Polishing Line

Not all polishing lines are created equal. When evaluating options, look beyond price tags to engineering and support delivering long-term value.

Number of Polishing Heads: Finding the Sweet Spot

Head count directly impacts final gloss levels and achievement speed. While more heads enable faster conveyor speeds, optimal numbers depend on primary materials you work with.

For instance, harder materials like granite may benefit from more heads to achieve deep, mirror like finishes without slowing the line.

Advanced Features: Automatic Abrasive Changers and Slab Readers

Leading-edge systems incorporate technology further reducing manual intervention and improving precision.

Automatic slab readers scan incoming slab shapes and sizes, activating only necessary heads to save energy and extend abrasive life. Automatic tool changers swap worn abrasive segments without stopping the line, maximizing uptime.

Build Quality & Support: What to Look for in a Manufacturer

Reliable machines start with solid construction. Look for manufacturers using heavy, rigid, vibration-dampening frames ensuring stability and polishing accuracy for decades.

At Dinosaw, we believe robust engineering is non-negotiable. Furthermore, inquire about technical support and parts availability. Machines of this scale become long-term partners - you need confidence in the support behind them.

Before final decisions, review all options. Our general guide on which stone polishing machine you should buy offers broader perspective.

Conclusion: Making the Final Decision

Upgrading to an automated polishing line represents a transformative step propelling your stone fabrication business into new leagues of productivity and quality.

It's the definitive solution for breaking through production bottlenecks and positioning your company to win larger, more demanding projects. However, this strategic decision requires holistic assessment of your business's finances, facility, and workforce.

Using this guide's framework, you can move from asking "if" to understanding "when" and "how." Analyze production data, evaluate operational readiness, and build solid business cases.

The path to industrial-scale production is calculated, and the right investment pays dividends for years. Ultimately, finished product quality defines your brand. For deeper understanding of the craft, explore our guide on how to get mirror-perfect stone finishes .

Ready to explore how an automated polishing line can transform your production? Contact our team for technical specs, pricing, and custom facility layouts. Discuss Your Project on WhatsApp.

Frequently Asked Questions (FAQs)

How much does an automatic polishing line cost?

Automatic polishing line costs vary significantly, typically from $100,000 to over $500,000. Final prices depend on polishing head count, brand, build quality, and advanced features. View it as a long-term investment in capacity and evaluate based on potential ROI, not just initial purchase price.

How many slabs can a polishing line produce per day?

Typical 12- to 16-head polishing lines produce 60 to 100+ finished slabs in 8-hour shifts. This translates to roughly 800-1,500 square meters, depending on slab size, material hardness, and desired finish. That's a 5-10x increase compared to most semi-automatic or manual methods.

What is the main advantage of an automated line over a bridge polisher?

Primary advantages are consistent quality and high throughput at scale. Automated lines ensure every slab has perfectly uniform finishes, eliminating human error and costly re-work, while continuous workflows dramatically increase daily slab processing numbers.

How much maintenance does a polishing line require?

Polishing lines require diligent daily, weekly, and monthly maintenance for optimal performance. Daily tasks include cleaning and checking abrasive wear. Weekly checks involve lubrication and moving parts inspection. Robustly built machines from reputable manufacturers like Dinosaw minimize unscheduled downtime, but preventative maintenance schedules are crucial for longevity.

Can an automated line polish different materials like marble and granite?

Yes, modern polishing lines are designed for versatility. They effectively polish wide material ranges from softer marble to hard granite and quartzite. The key is using correct diamond abrasive sequences and adjusting machine parameters like conveyor speed and head pressure to suit specific materials being processed.

How much space do I need to install a polishing line?

Significant space is required. Complete lines, including loading and unloading tables, typically need long, narrow footprints of at least 20-30 meters (65-100 feet) in length and 5-7 meters (16-23 feet) in width. You must also account for clearance around machines for safe operation and maintenance.

English

English 中文

中文