Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

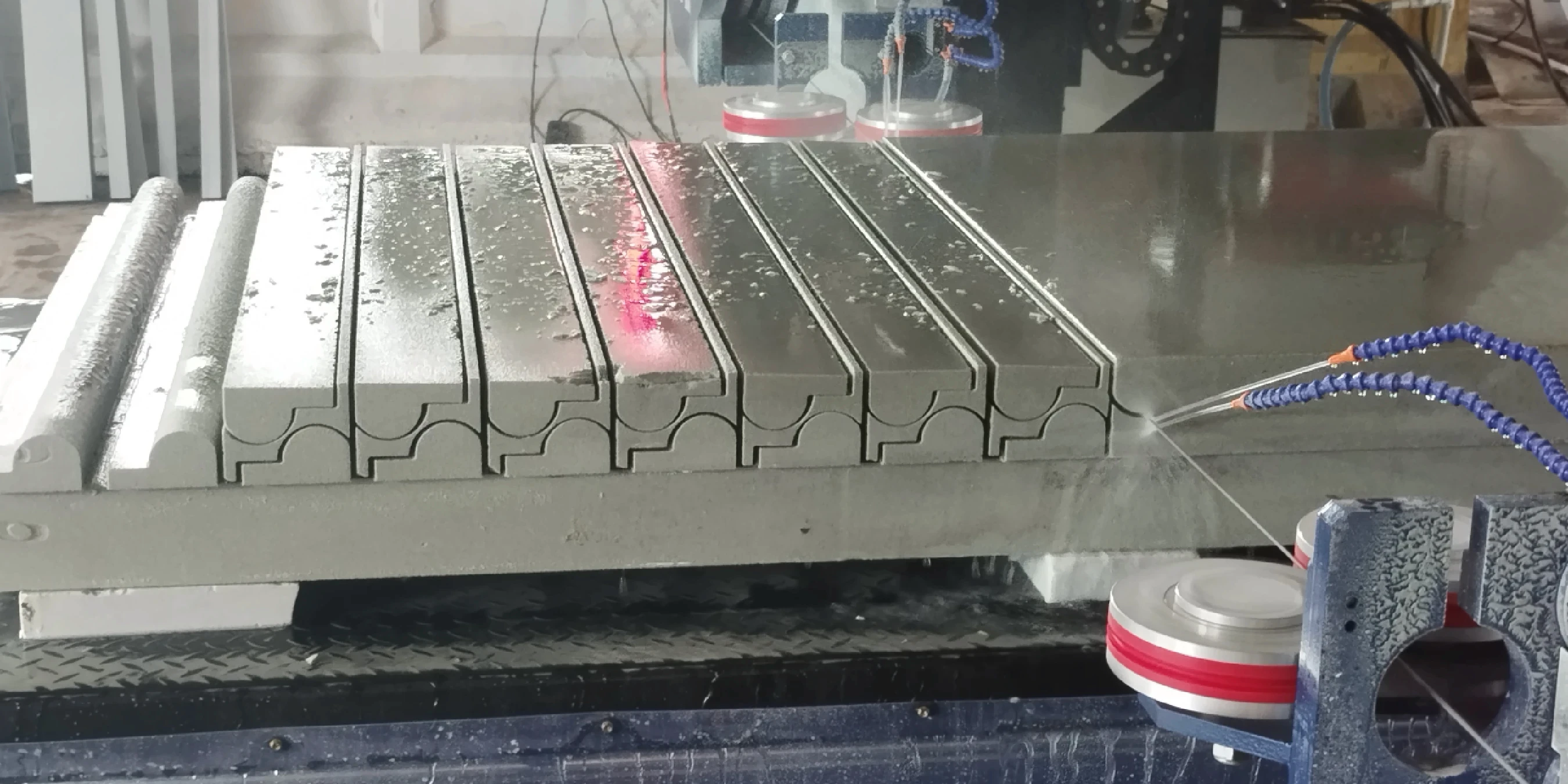

Maximize uptime with our O&M guide for the CNC Diamond Wire Saw. Covers daily checks, troubleshooting, maintenance schedules, and safety tips for operators.

A machine's performance depends on disciplined operation and proactive maintenance. This practical guide provides machine operators and technicians with actionable SOP checklists, quick-reference troubleshooting for common errors, and a clear preventive maintenance schedule. Following these steps is the key to maximizing uptime, ensuring precision, and maintaining a safe workshop.

From startup to shutdown, this guide covers the essential knowledge you need to operate and maintain your investment effectively. For a deeper understanding of the machine's components mentioned here, refer to our CNC Wire Saw Pro Technical Deep Dive.

SOPs for CNC Wire Saw Operation (startup, changeover, shutdown)

Consistency is key to operational excellence. Use these checklists to standardize your daily workflow.

Startup Checklist

- Check emergency stops are disengaged.

- Inspect diamond wire for frays or damage.

- Inspect guide wheels for wear or debris.

- Verify water system has adequate flow.

- Power on and home all axes (X, Y, Z + A; include B for 5-axis).

- Verify rotary zero calibration.

Job Changeover Checklist

- Clear worktable of previous workpiece and debris.

- Securely clamp the new workpiece.

- Load the correct G-code program.

- Verify program kinematics (4-axis vs 5-axis mode).

- Set the program's zero point (WCS).

- Run a dry run if the program is new or complex.

Shutdown Checklist

- Return axes to home position.

- Clean slurry and stone dust from the worktable and guide wheels.

- Wipe down guide rails and lubricate if necessary.

- Turn off water supply.

- Follow the proper power-down sequence via the controller.

- Engage main electrical disconnect if required.

Troubleshooting CNC Diamond Wire Saw (wire breakage, errors)

When issues arise, a systematic approach to troubleshooting saves time. Here’s a quick guide to common problems.

1. Premature Wire Breakage

Issue: The diamond wire snaps before its expected lifespan.Diagnosis: Is the wire tension too high or too low for the material? Are the guide wheel grooves worn, causing a pinch point? Is the feed rate too aggressive?Solution: Verify tension settings. Inspect guide wheels for a ‘V’ shape instead of a ‘U’ shape and replace if worn. Reduce the feed rate.

2. Inaccurate Cuts

Issue: The finished part does not match the program dimensions.Diagnosis: Is the wire vibrating excessively? Is the workpiece securely clamped? Have the axes been calibrated recently?Solution: Check wire tension. Re-clamp the workpiece. Run the machine's axis calibration routine. If the issue persists on a rotary axis, it may be a misalignment.

3. Rotary Axis Misalignment

Issue: Cylindrical or profiled cuts are skewed or off-center.Diagnosis: Was the axis homed correctly? Is there a CNC error code related to the encoder? Is there physical "slop" or backlash in the axis?Solution: Re-run the homing sequence. Check for controller errors. Manually check for mechanical looseness. If backlash is present, professional service is likely required.

4. Motor Overheating

Issue: The main drive motor feels excessively hot to the touch or triggers a thermal alarm.Diagnosis: Is the cutting load too high (feed rate)? Is the motor's cooling fan blocked with dust? Are the motor bearings making a grinding noise?Solution: Reduce cutting parameters. Clean the motor's exterior and fan housing. If bearing noise is present, schedule a replacement.

5. Water Leaks

Issue: Water is spraying or dripping from areas other than the cutting zone.Diagnosis: Are cooling hose fittings loose? Is a hose cracked or perforated? Is the slurry drain clogged, causing overflow?Solution: Tighten all hose clamps and fittings. Inspect hoses for wear and replace if damaged. Clear any blockages in the slurry collection and drainage system.

Preventive Maintenance for wire saw (daily/weekly/monthly/quarterly)

This schedule is a general guideline. Your own schedule should be adapted based on machine usage and the abrasiveness of the materials you cut.

| Frequency | Task |

|---|---|

| Daily | Clean slurry from worktable, guide wheels, and machine frame. Check diamond wire for visible damage. Verify safety guards are in place. |

| Weekly | Inspect guide wheel grooves for wear. Lubricate all specified points (linear rails, lead screws). Check water filter and clean if necessary. Check wire tensioning system for smooth operation. |

| Monthly | Check all electrical cabinet filters and clean/replace as needed. Tighten any loose electrical connections (with power off and locked out). Run axis calibration routine. Inspect drive belts for wear or damage. |

| Quarterly | Perform a full system diagnostic from the control panel. Check and adjust rotary axis backlash if required. Inspect all hydraulic/pneumatic lines for leaks or wear. Review service logs for recurring issues. |

Operator tips (reduce vibration, guide wheel inspection)

- Reducing Vibration on Brittle Materials: When cutting foam ceramic or brittle granite, try slightly reducing wire tension below the standard setting. This can absorb micro-vibrations and prevent chipping at the edges. Also, ensure your water flow is high to flush particles immediately.

- Checking Guide Wheel Wear: A simple way to check guide wheel wear without calipers is to use a new strand of the diamond wire itself. Fit it into the groove. If it sits deep and you can see the top of the groove on both sides, it's good. If the wire sits flush or proud of the groove surface, the wheel is worn out and will break your wire.

Safety & Compliance (OSHA silica, LOTO, PPE)

Operating heavy machinery carries inherent risks. Adherence to safety protocols is mandatory.

Personal Protective Equipment (PPE):

Always wear ANSI-rated safety glasses, waterproof steel-toed boots, and appropriate gloves. A respirator is required when dry dust is present.

Electrical Safety (Lockout/Tagout):

Before any maintenance, the machine must be de-energized and locked out. Follow the procedures outlined in official standards like OSHA: Lockout/Tagout. Never bypass safety interlocks.

Dust & Slurry Management:

Cutting stone, concrete, and quartz creates respirable crystalline silica, a known carcinogen. The wet cutting process helps suppress dust, but proper ventilation and water management are critical. For more information, refer to guidelines from OSHA: Respirable Crystalline Silica and NIOSH: Crystalline Silica. Slurry must be disposed of according to local environmental regulations (e.g., EPA in the US, REACH in the EU).

Mechanical Safety:

Keep all machine guards in place during operation. Know the location of all emergency stop buttons and ensure they are never obstructed.

Frequently Asked Questions

Where to buy diamond wire & spares for cnc wire saw?

You can order official replacement wire, guide wheels, and other spare parts directly from DINOSAW or an authorized distributor. Using OEM parts is recommended to ensure compatibility and maintain your machine's warranty and performance.

Guide wheel maintenance-how often to replace?

Guide wheel lifespan depends on usage and the materials cut. A weekly inspection for groove wear is recommended. As a general rule, with heavy, single-shift use on hard granite, you might expect to replace them every 3-6 months. Softer materials will result in longer life.

Lubrication for wire saw rails/screws-what grease?

Use a high-quality lithium-based grease for linear guide rails and ball screws. Refer to the official CNC Diamond Wire Saw Pro manual; exact lubricant specifications may vary by component.

Can operators perform monthly wire saw maintenance?

Yes, a trained operator or in-house technician can perform daily, weekly, and monthly maintenance tasks. This includes cleaning, lubrication, and basic calibration. More complex tasks like quarterly diagnostics or major repairs should be handled by a certified technician.

Wire saw error codes-first steps to fix?

First, write down the exact error code and message. Consult the troubleshooting section of the machine manual for that specific code. Often, it will point to a simple issue like a sensor being blocked or a safety interlock that needs to be reset.

Operator training for cnc wire saw-on‑site options?

Yes, on-site training is typically part of the installation package and is highly recommended. Proper operator training is one of the most important factors for machine uptime and longevity. Contact our sales or support team to arrange training for new staff.

How do I properly perform an axis calibration?

The CNC controller will have a built-in calibration routine, typically found in the settings or maintenance menu. This process usually involves using a precision dial indicator or probe to measure axis movement and allowing the software to compensate for any detected error. Always follow the specific steps in your machine's manual.

English

English 中文

中文