Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Discover the right stone profiling machine for your factory. Our 2025 guide compares CNC, edge, and 3D profilers for granite, marble, and even glass applications.

Manual stone profiling is costing you money. Every day your competitors automate production with stone profiling machines while you rely on handheld tools, you're losing contracts, wasting materials, and limiting your profit potential.

A stone profiling machine transforms raw stone into perfectly finished countertop edges and architectural elements with precision impossible to achieve by hand. It's not just equipment - it's your path to higher profits, faster production, and premium projects.

Beyond the Flat Edge: Why Manual Profiling is Costing You Money

Manual work creates bottlenecks that limit your factory's output and ability to take on larger, more lucrative contracts. Even experienced technicians can't guarantee that the tenth ogee edge will match the first, leading to quality control issues and client dissatisfaction.

According to the Stone World Annual Industry Report , fabricators are increasingly investing in automation to meet client expectations for precision. Manual profiling also carries higher risks of material waste and safety hazards from dust and improper tool handling.

The Core Technology: How a Stone Profiling Machine Works

At its heart, a stone profiling machine is a specialized tool designed to shape stone edges and surfaces with precision. It automates labor-intensive manual processes using robust components and tooling to deliver flawless results consistently.

Key Components

A typical profiling machine consists of several critical parts working together. The spindle is the powerhouse - a high-torque motor that spins cutting tools at thousands of RPM. The quality and power of the spindle directly determine the machine's ability to handle hard materials like quartzite. The profiling wheels or cutting heads are diamond-impregnated tools that do the actual shaping. A guide system - ranging from simple roller guides that trace templates to highly precise, software-driven CNC systems - directs the spindle to create desired shapes. Constant water flow is essential for cooling tooling and removing slurry.

The Process

The workflow transforms digital designs or physical templates into finished stone products. In a CNC-driven process, CAD files (like .dxf) are loaded into the machine's software. The machine then automatically executes series of passes, using progressively finer-grit diamond wheels to grind, shape, and often polish stone to exact specified profiles.

This automated, multi-pass approach ensures superior finishes without human error risk.

Tooling is Everything

Final quality of profiled edges depends entirely on tooling used. Diamond profiling wheels are engineered for specific shapes, from common styles like Full Bullnose and Ogee to custom architectural designs.

These wheels are available in different "bonds" (metallic matrix holding diamonds) suited for various stone types. Harder bonds work for soft stones like marble, while softer bonds are required for dense materials like granite to ensure fresh diamonds are exposed as tools wear. Choosing right tooling is critical for achieving chip-free finishes and maximizing tool life.

Need a specific profile for a project? Our experts can match you with the right machine and tooling for any design. Chat with us on WhatsApp for a free consultation.

Types of Stone Profiling Machines: Finding the Right Fit for Your Shop

Not all profiling machines are created equal. The right choice depends entirely on your factory's primary applications, production volume, and business goals. We've broken down the main categories to help you make informed decisions.

Application 1: High-Volume Countertop Edge Profiling & Polishing

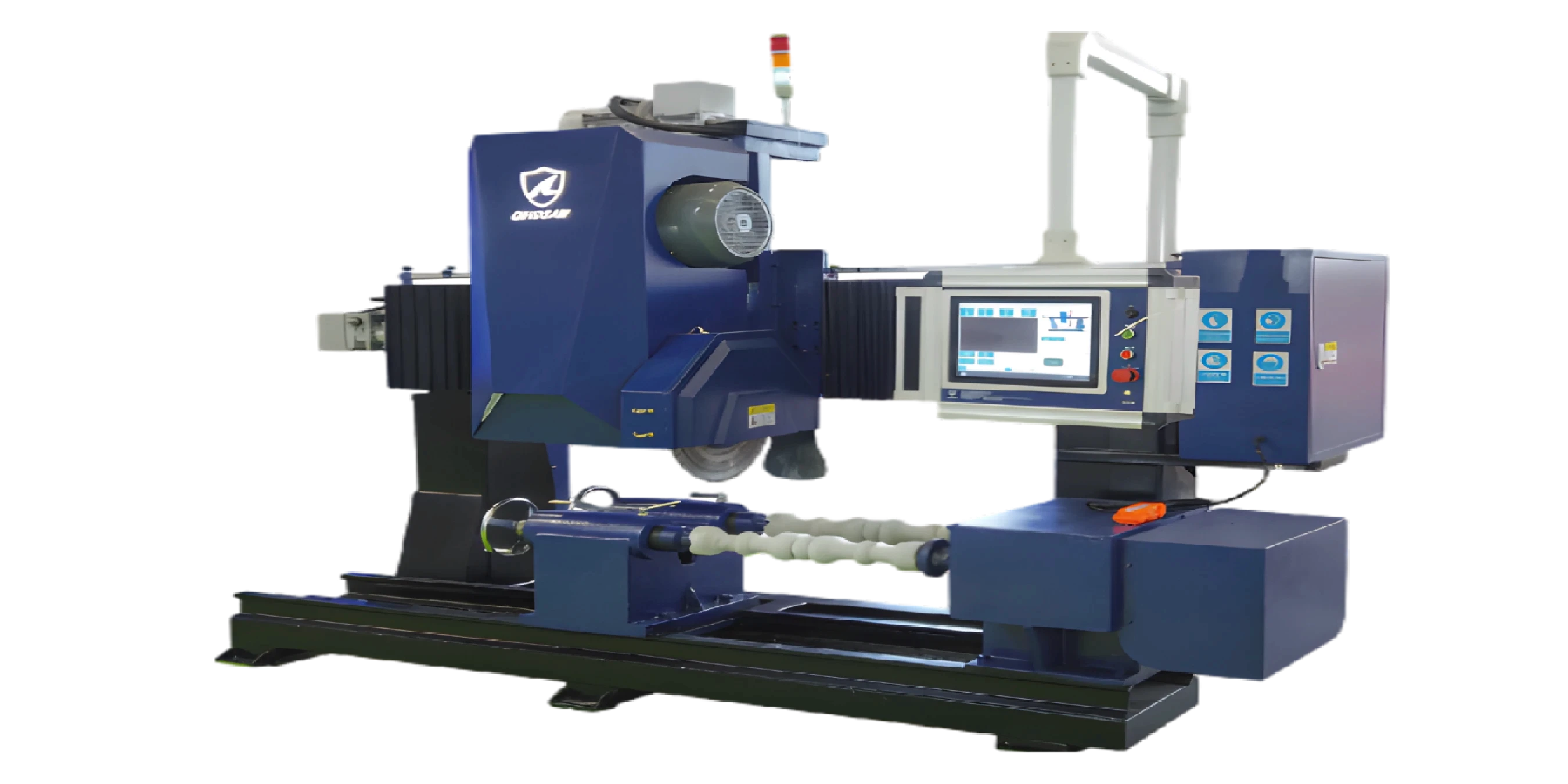

- Machine Type: Bridge Type Automatic Profile Polishing Machine

- Core Advantage: This machine is the workhorse for countertop fabricators. It's expertly designed to automate finishing of straight and simple curved edges in high volumes. By using templates or pre-programmed shapes, it ensures every countertop piece has perfectly consistent edges, dramatically increasing factory throughput and reducing labor cost per linear foot.

Application 2: Complex 3D Shaping & Architectural Elements

- Machine Type: Integrated CNC Stone Profiling Machine

- Core Advantage: When projects demand more than simple edges, a full CNC profiler is essential. These machines process high-profit architectural components like complex window surrounds, decorative moldings, and fireplace mantels.

For specialized work, the Column Cap & Base Profiling Machine uses vertical lathe structure for perfect 360-degree shaping of column elements, turning raw stone blocks into high-value architectural art. This capability allows shops to bid on more creative and lucrative commercial and residential projects.

Application 3: High-Precision Cutting & Integrated Profiling

- Machine Type: Multi-Function 3, 4, 5-Axis CNC Bridge Saws

- Core Advantage: For modern, versatile fabrication shops, a 5-axis bridge saw offers powerful combination of cutting and profiling. It can perform all necessary cuts for countertops - including sink cut-outs and mitered edges - and then switch to profiling tools to finish edges.

This integrated approach saves floor space and reduces material handling, making it excellent choice for shops that value flexibility and streamlined workflows.

Application 4: Expanding Your Business with Dual-Use Material Capabilities

- Machine Type: CNC Edging Machine for Glass & Stone Dual-Use

- Core Advantage: This machine is strategic investment for fabricators looking to diversify offerings. With capability to deliver high-precision polishing on both stone (granite, marble) and glass, it opens new revenue streams.

A shop can produce stone countertops and custom glass shower enclosures for the same project, increasing value of each contract. It's the ideal tool for fabricators aiming to become one-stop solutions for high-end residential and commercial projects.

Connecting Machine Capabilities to Your Bottom Line

Investing in a stone profiling machine is strategic decision that pays dividends through increased efficiency, higher quality, and expanded capabilities. Primary ROI comes from drastic reduction in manual labor costs and ability to complete jobs faster, increasing your factory's overall capacity.

What's more, perfect consistency achieved by CNC machines significantly reduces material waste and costly rework.

When selecting machines, look beyond initial price. Consider rigidity of machine structure, as this directly impacts cutting accuracy and tool life. Ensure software is user-friendly and compatible with standard design files. Most importantly, evaluate manufacturer's after-sales support and training programs.

As confirmed by research from MarketsandMarkets on the Stone Processing Market , global demand for processed stone is growing, and investing in efficient technology is key to capturing this growth. A reliable machine with strong technical backing is asset that will generate revenue for years to come.

Don't let manual processes limit your profits. Let's design the perfect profiling solution for your factory. Contact a DINOSAW expert on WhatsApp today

Frequently Asked Questions (FAQs)

What is the main difference between a stone profiler and an edge polisher?

A stone profiler is designed to shape and create specific profiles (like bullnose or ogee) on stone edges, while an edge polisher focuses on bringing shaped edges to high-gloss finishes. Many modern machines, such as our Flat Edge or Bullnose? How to Actually Choose the Right Stone Edge Polisher , can perform both functions in single, automated processes.

Can a CNC router be used for stone profiling?

Yes, CNC routers equipped with correct tooling and robust, high-torque spindles can be used for stone profiling and carving. However, dedicated profiling machines are often more rigid and specifically optimized for heavy-duty forces involved in shaping stone edges, typically resulting in faster feed rates and longer tool life for high-volume production.

How much does a professional stone profiling machine cost?

Cost varies widely based on capability, from approximately $20,000 for entry-level bridge-type profilers to over $150,000 for advanced 5-axis CNC systems or specialized architectural profilers. Key cost factors include machine size, spindle power, software sophistication, and automation level (e.g., automatic tool changing).

What kind of maintenance does a stone profiling machine require?

Routine maintenance is crucial for longevity and precision. This includes daily cleaning to remove slurry, weekly checks of guide rails and lubrication systems, and regular inspection of profiling wheels for wear. It's also vital to adhere to all equipment safety protocols, as outlined by standards like the OSHA Machine Guarding eTool (https://www.osha.gov/etools/machine-guarding), to ensure safe operating environments.

Which stone types are most difficult to profile?

Ultra-compact surfaces and dense quartzites are most challenging materials to profile due to their hardness and brittleness, which can lead to chipping. Successfully profiling these materials requires highly rigid machines to minimize vibration, high-quality spindles, and specialized diamond tools with softer bond matrices to prevent premature glazing and ensure clean cuts.

How do I choose the right diamond profiling wheel for my project?

Choosing right wheels depends on three factors: stone material, desired profile shape, and machine type. For hard materials like granite, use soft-bond wheels. For softer marble, use hard-bond wheels. Profile shape must match your design (e.g., A, B, E, V shapes). Always ensure wheel's arbor size and RPM rating are compatible with your machine's specifications.

Is a profiling machine a better investment than a 5-axis bridge saw?

It depends on your business focus. If your primary work is high-volume countertop production with standard edges, dedicated profiling machines offer unmatched speed and efficiency. If your shop handles wide variety of custom jobs requiring complex cuts, sink cut-outs, and profiling, 5-axis bridge saws provide greater versatility in single machines, saving space and reducing material handling.

English

English 中文

中文