Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Unlock the business value of the CNC Diamond Wire Saw Pro. This executive guide covers ROI levers like throughput, labor costs, and material yield. Plan your path.

Acquiring a CNC diamond wire saw is a strategic investment in new capabilities and market differentiation, not just a capital expense. This executive guide provides a clear roadmap for C-suite leaders and operations managers to understand the key ROI levers-from material yield to labor reduction-and outlines a phased implementation plan (Pilot → Standardize → Scale) to maximize returns.

CNC Wire Saw ROI in 60 Seconds (materials, use cases)

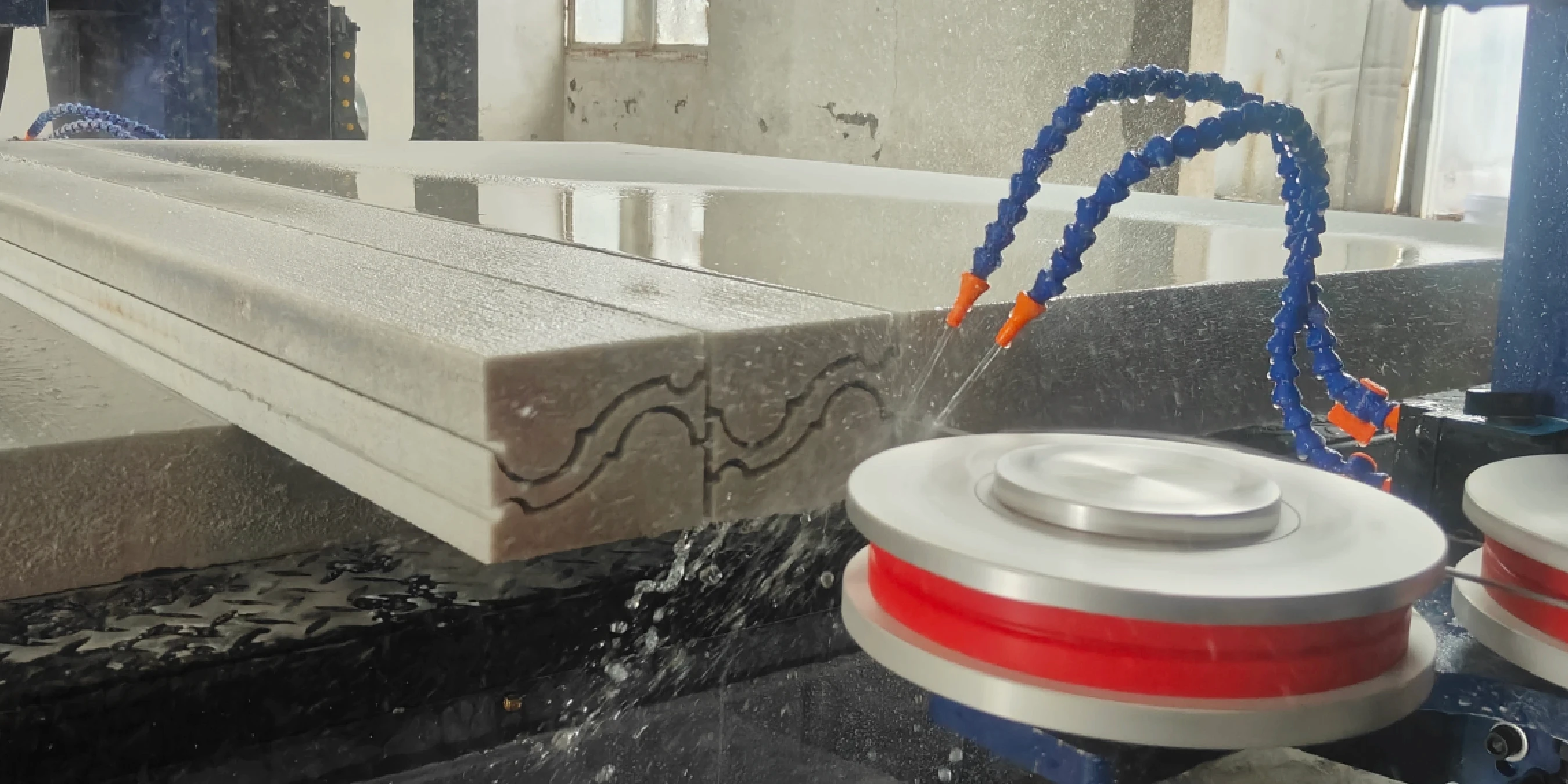

At a strategic level, the CNC Diamond Wire Saw Pro is a high-precision automated machine that unlocks new revenue streams by overcoming the limitations of traditional cutting methods. It uses a thin, diamond-coated wire to execute complex designs in hard materials that are otherwise difficult or impossible to fabricate. It comes as a 4-axis standard configuration for most profiling work, with an optional 5-axis upgrade for the most complex 3D forms.

This capability allows workshops to profitably produce high-value items like Roman columns, intricate lettering, and curved slabs from materials including marble, granite, limestone, basalt, travertine, quartzite, concrete, foam ceramic, quartz glass, and fiberglass (FRP)-all while reducing waste and labor dependency.

Quick‑Start Decision Map to Buy a cnc wire saw

The path to selecting the right machine configuration follows a logical flow. Before diving into financial models, this simplified strategic sequence ensures your technical requirements are aligned with business goals:

- Assess Material & Size: Define the largest and most common workpieces you will process to determine the required model (e.g., YXSJ-2500-16pro for smaller blocks up to YXSJ-350016pro for large ones).

- Select Axis Configuration: Determine if your core business involves profiling and 2.5D shapes (4-axis is sufficient) or true 3D forms and undercuts (5-axis is necessary).

- Define Required Complexity: Evaluate the intricacy of your designs. This will influence decisions on software, training, and operator skill requirements.

- Calculate Key ROI Levers: Quantify the expected impact on the key business metrics detailed in the next section.

- Select the Optimal Model: Synthesize the above points to make a final, data-backed selection.

ROI Levers (throughput, yield, labor, accuracy, consumables)

The business case for the CNC Wire Saw rests on several powerful, quantifiable ROI levers. Frame your analysis around these core metrics.

1. Throughput & Cycle Time

Automation is the engine of operational efficiency. Unlike manual processes, the CNC wire saw can run continuously with minimal supervision, enabling 24/7 operation on large projects. This dramatically increases throughput and reduces lead times, allowing your business to take on more work and deliver faster than competitors.

3. Labor Hour Reduction

The machine transforms labor dynamics. It shifts the paradigm from multiple skilled artisans performing labor-intensive manual work to a single operator overseeing an automated process. This not only reduces direct labor costs but also mitigates risks associated with skilled labor shortages and allows you to reallocate your most valuable talent to design, quality assurance, and customer-facing roles.

2. Kerf Loss & Material Yield

With a thin 3-15 mm diameter wire, the kerf (material removed during the cut) is minimal. Compared to thick blades on traditional saws, this translates to significant material savings. On expensive blocks of stone, improving yield by even a few percentage points can generate tens of thousands of dollars in savings annually, directly boosting profitability.

4. Dimensional Accuracy & Finish

High precision means the part is cut correctly the first time. This drastically reduces costly rework, secondary finishing steps, and material scrap. The smooth finish produced by the wire saw often eliminates the need for subsequent grinding or polishing, further compressing the production cycle and its associated costs.

5. Consumables & Energy

The total cost of ownership analysis must include operational expenditures. The Pro series is engineered for efficiency with a 15 kW main motor and DINOSAW-reported water consumption of 3 m³/h. While diamond wire is a consumable, its cost and replacement cycle should be compared against the resharpening, replacement, and higher energy draw of large-diameter blades used in conventional saws.

6. Capability ROI

This is the most powerful lever. The machine doesn't just make existing processes more efficient; it enables entirely new, high-margin business. The 5-axis option allows you to bid on complex 3D projects that were previously inaccessible. The standard 4-axis configuration unlocks profitable profiling work, turning your shop into a go-to provider for custom architectural and monumental pieces.

Knowledge Hub (applications, technical, selection, O&M)

This guide is the strategic capstone of a series designed to support your entire decision-making process. Use these resources to drill down into specific areas:

- For what this wire saw machine can do, see our Applications & Case Studies guide of CNC wire saw Pro.

- To understand how it works, read the Technical Deep Dive of CNC wire saw Pro.

- To choose the right model, use our Buyer's Guide of CNC wire saw Pro.

- To ensure smooth operation, follow the O&M Best Practices of CNC wire saw Pro.

A Note on Safety, Compliance, and Risk Mitigation

A sound investment is also a safe one. The DINOSAW Pro series is designed according to fundamental safety principles outlined in standards like ISO 12100 (Safety of Machinery) and IEC 60204-1 (Electrical Equipment of Machines). What’s more, DINOSAW machines are also compliant with CE and ISO certifications.

From a workforce perspective, managing health and safety risks, such as those from respirable crystalline silica dust, is non-negotiable. Following guidance from bodies like OSHA and NIOSH is essential for protecting your employees and ensuring regulatory compliance, mitigating operational and financial risk.

Frequently Asked Questions

CNC wire saw payback period-typical range?

The payback period depends heavily on your use case. For a shop transitioning from manual methods to automated profiling, the labor savings and increased throughput can lead to a payback period of 6-18 months. For shops using it to enter new high-margin markets, the payback can be even faster, driven by increased profitability.

Can you model wire saw ROI for my use case?

Absolutely. Our technical sales team can work with you to build a custom ROI model. By inputting your current costs (labor, material), block sizes, and target applications, we can project the financial impact of integrating a CNC wire saw into your operations, providing a data-driven foundation for your investment decision.

Installation disruption-how long and how to plan?

Disruption can be minimized with proper planning. The main phases are foundation preparation (which can be done in advance) and machine delivery/commissioning. A well-planned installation, scheduled during a slower period, can be completed in 1-2 days, with operator training occurring concurrently.

English

English 中文

中文