Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Unlock high-margin revenue. Our 2025 business guide details 15 profitable CNC stone carving projects, from architectural art to memorials, with machine advice.

The competitive world of stone fabrication no longer rewards volume alone. Standard countertop production has become a race to the bottom on pricing. Smart business owners are asking the right question: where's the real profit hiding?

The answer lies in high-margin CNC stone carving projects. This shift transforms your operation from a simple fabricator into a premium artisan workshop. Instead of competing on price, you're selling craftsmanship, uniqueness, and artistic value.

This comprehensive guide reveals 15 specific, profitable CNC stone carving projects. We'll explore profit potential, target markets, and exact machinery requirements. More importantly, you'll learn how to turn raw granite and marble blocks into significant revenue streams.

Why CNC Stone Carving Commands Premium Prices

The demand for bespoke stonework isn't just trending—it's a fundamental market shift. Luxury residential, commercial, and memorial sectors increasingly seek unique, personalized pieces that standard fabrication simply cannot deliver.

From Bulk Slabs to High-Value Custom Art

Consider the contrast in value creation. According to the U.S. Geological Survey (USGS) Mineral Commodity Summaries 2024 , billions of tons of crushed stone are produced annually. Yet the value per ton remains remarkably low.

Dimensional stone for artistic and architectural purposes commands exponentially higher prices. A CNC machine transforms a standard marble block into a 3D wall panel or sculpture worth many times its raw material cost. The difference? Added artistry and precision.

Market Growth in Architecture, Design, and Memorials

The global decorative stone market shows robust growth. Industry analysis from Grand View Research projects steady expansion driven by construction and real estate sectors.

Architects increasingly specify custom stone features to create distinctive, high-end environments. The memorial and headstone market remains recession-proof, where customization and quality justify premium pricing.

Understanding High-Margin Profit Models

High-margin projects succeed based on the gap between production cost and perceived value. Standard countertops have well-defined market prices. A custom-carved marble fireplace, however, is functional art.

Price determination shifts from commodity pricing to value-based pricing. Factors like craftsmanship, uniqueness, and design complexity drive customer decisions. A powerful CNC machine delivers unparalleled precision and efficiency in creating these premium pieces.

Architectural & Commercial Projects: High-Ticket Client Opportunities

This category represents the highest potential for large, profitable contracts. Target clients include architects, luxury builders, and corporations who value precision and willingly pay premiums for statement pieces.

3D Wall Panels & Feature Walls

- Profit Potential: High. Large-scale installations become room centerpieces. Material costs represent a fraction of final installed prices.

- Target Market: High-end hotels, corporate lobbies, luxury residential builders, interior design firms.

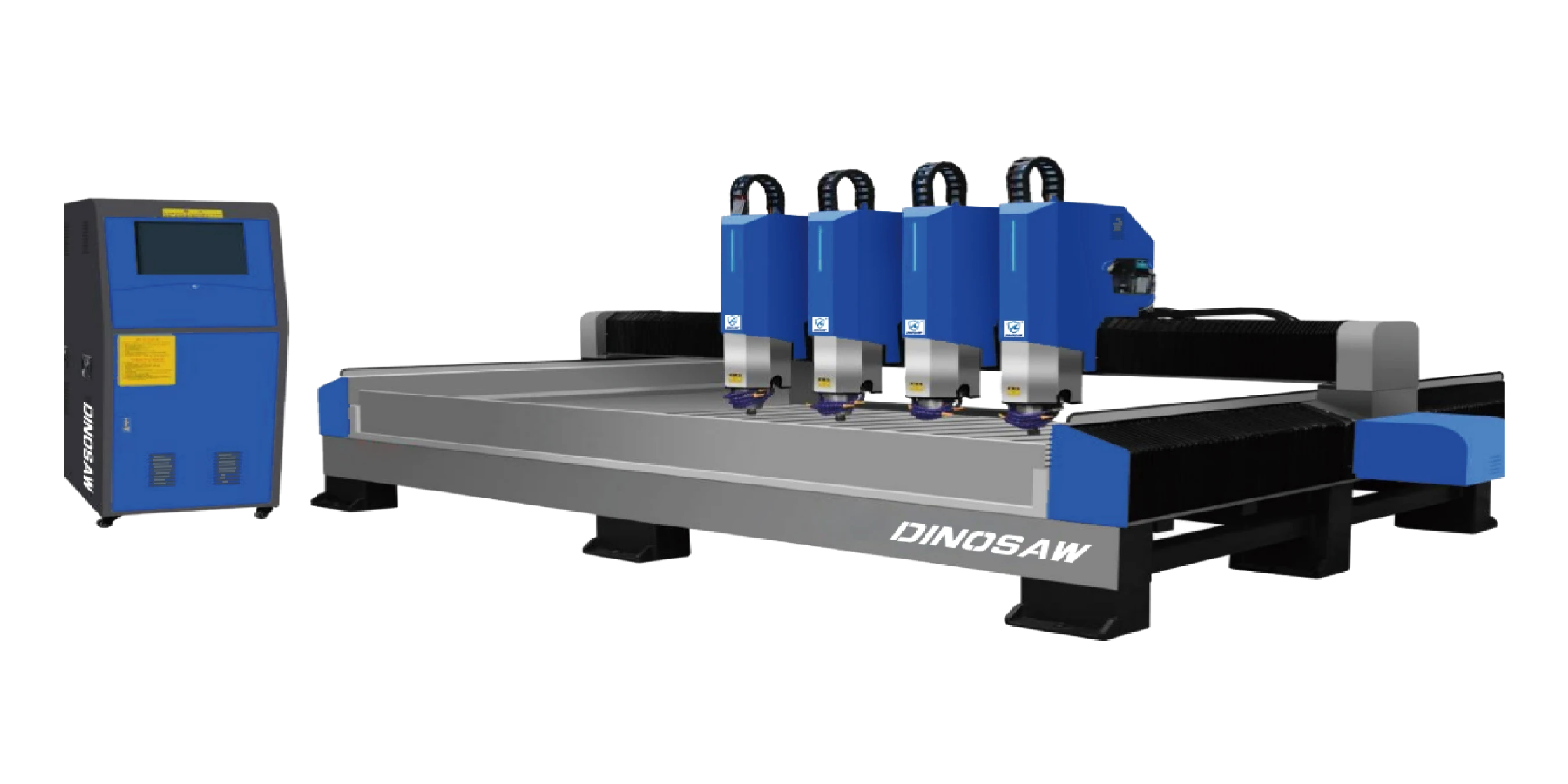

- Recommended Equipment: 5-Axis CNC Bridge Saw for Sinks & Countertops for panel surfaces, 7 Axis Robotic Arm for 3D Stone Carving & Cutting for complex undulating designs.

Custom Fireplace Surrounds

- Profit Potential: High. Classic high-value items. Intricate carvings and detailed mouldings command $10,000-$50,000+ depending on stone and design complexity.

- Target Market: Custom home builders, luxury residential architects, high-end renovation homeowners.

- Recommended Equipment: Bridge saw for core profiles, CNC Stone Engraving Machine for 3D Relief & Tombstones for detailed reliefs and intricate patterns.

Architectural Mouldings & Corbels

- Profit Potential: Medium to High. Individual pieces may be smaller, but project volumes can be substantial. CNC precision and repeatability provide competitive advantages.

- Target Market: Historical restoration contractors, luxury builders, architects.

- Recommended Equipment: Integrated CNC stone profiling machine with custom diamond blades for complex profiles and undercuts.

Corporate Logos & Signage

- Profit Potential: Medium to High. Companies invest heavily in branding. A carved stone logo in a corporate lobby makes a powerful statement requiring absolute precision.

- Target Market: Corporations, universities, government buildings, luxury retail brands.

- Recommended Equipment: CNC Stone Engraving Machine for 3D Relief & Tombstones for precision V-carve engraving and both inlaid or relief logo work.

Ready to tackle high-ticket architectural projects? Chat with our CNC specialists on WhatsApp

Interior Design & Luxury Home Goods: Functional Art Markets

This market focuses on bespoke items for discerning homeowners seeking functional art. These projects often emphasize design components and can build strong brand reputation in luxury markets.

Custom Stone Sinks & Bathtubs

- Profit Potential: High. Transform solid marble or travertine blocks into functional sculptures selling for tens of thousands in luxury showrooms.

- Target Market: Interior designers, bathroom showrooms, luxury market homeowners.

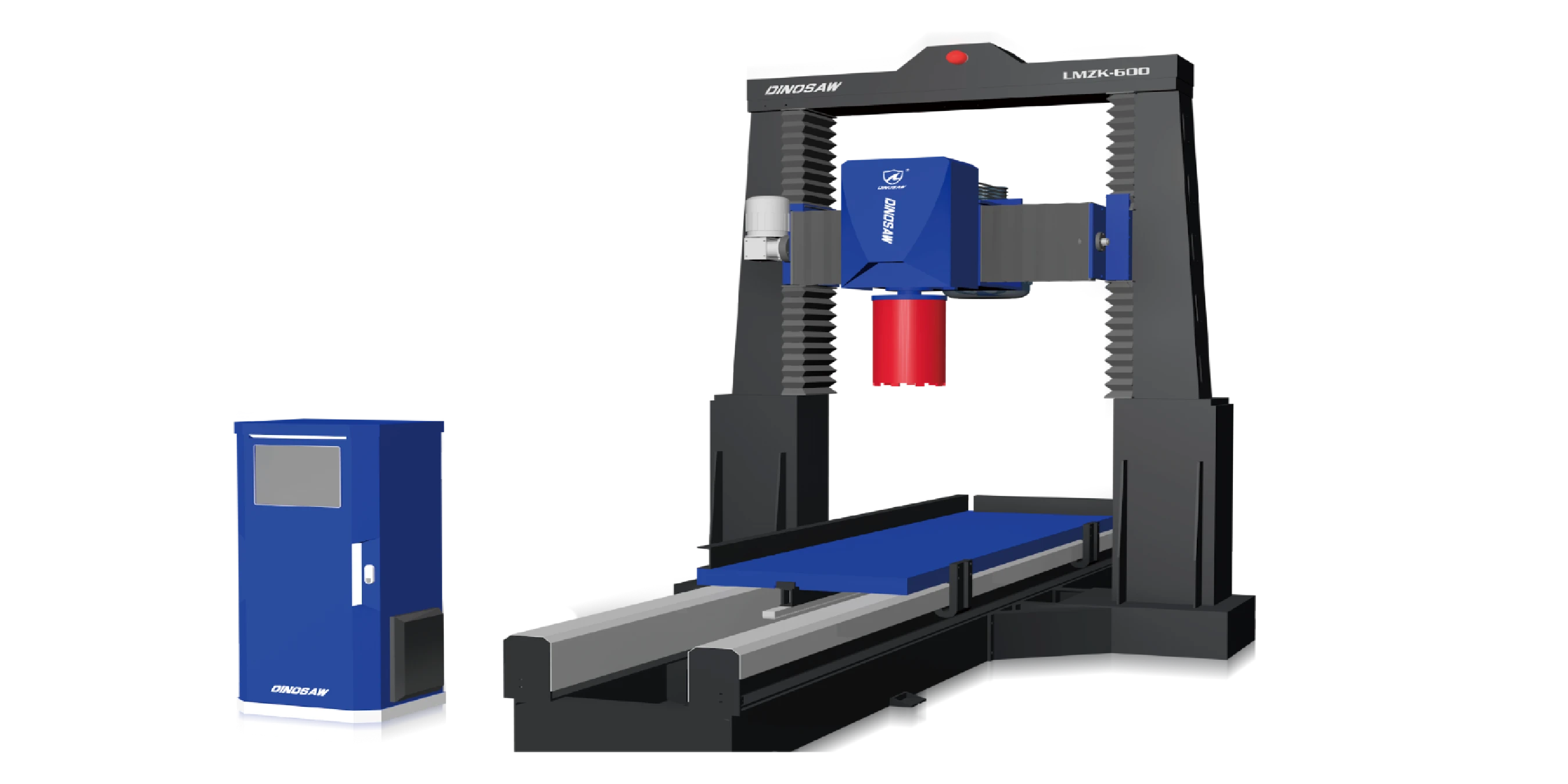

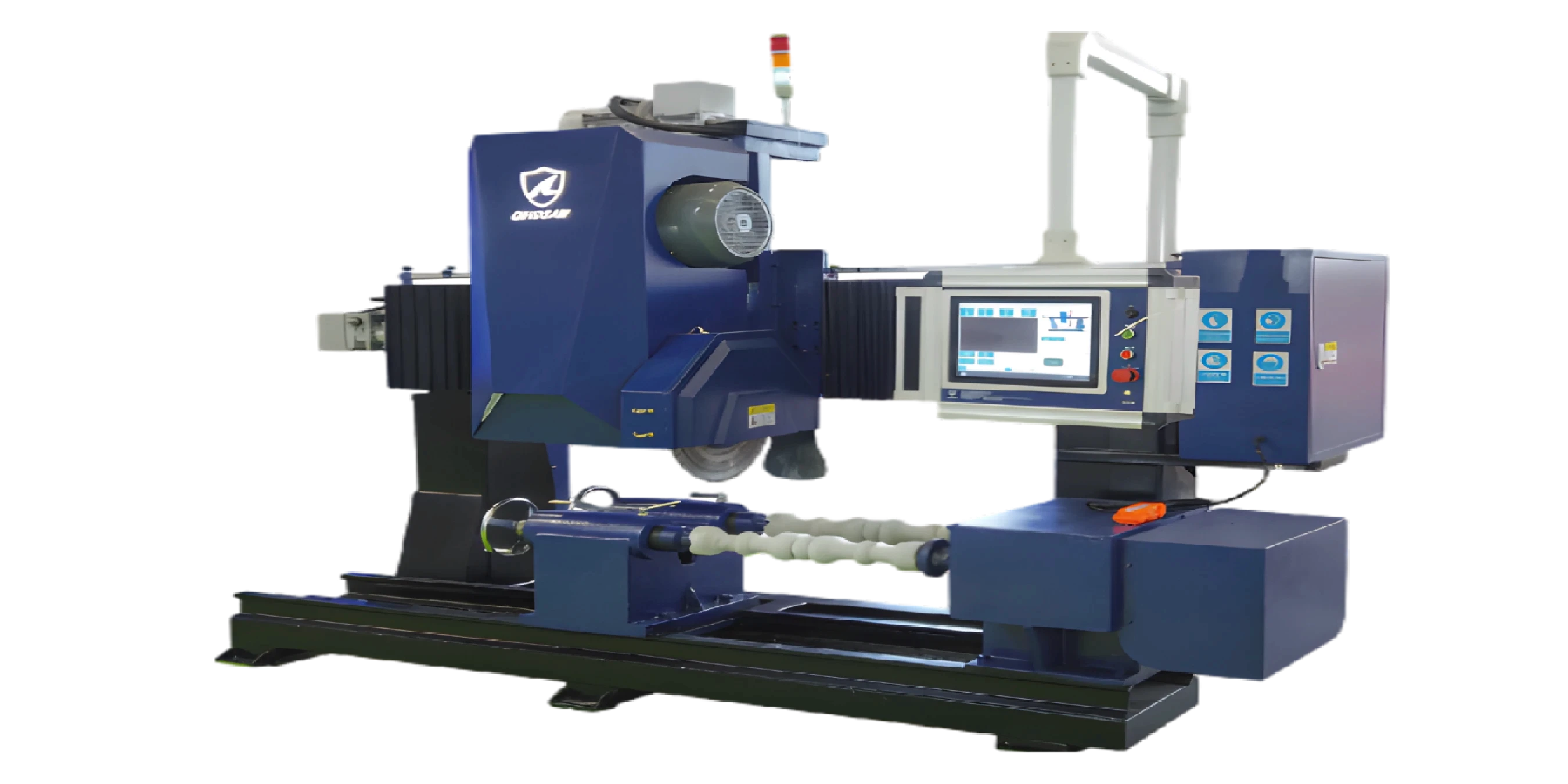

- Multi-Step Process: Automatic Stone Drilling Machines for hollowing, Pro CNC Wire Saw for Large Block & 3D Shape Cutting for rough profiles, 5-Axis CNC Bridge Saw for Sinks for fine shaping and polishing.

🪑 Parametric Stone Furniture (Tables, Benches)

- Profit Potential: High. Parametric design with fluid, ribbon-like forms represents growing trends in high-end furniture. Nearly impossible to create by hand but perfect for multi-axis CNC.

- Target Market: Avant-garde furniture designers, art galleries, wealthy private collectors.

- Equipment Selection: Pro CNC Wire Saw for Large Block & 3D Shape Cutting for monolithic pieces, 5-Axis CNC Bridge Saw for assembled furniture, CNC Stone Engraving Machine for surface patterns.

Intricate Floor Medallions & Inlays

- Profit Potential: Medium. Low material usage but high labor value for design and precision cutting. Perfect for dramatic entrances in homes or hotels.

- Target Market: Flooring contractors, interior designers, hotel developers.

- Precision Required: 5-Axis CNC Waterjet for Precision Stone & Metal Cutting ensures tight, seamless fits between different stone types with zero chipping.

Stone Vases & Decorative Art Pieces

- Profit Potential: Medium. Allows for artistic expression and can be sold through online platforms or art galleries. Great way to use smaller, high-quality off-cuts.

- Target Market: High-end home decor stores, art galleries, direct-to-consumer online.

- Equipment Options: CNC Stone Lathe for Architectural Columns & Balusters for symmetrical vases and urns, 5-axis CNC for abstract sculptures.

Memorials & Monuments: Recession-Proof High-Margin Market

The memorial market values quality, personalization, and artistry over price considerations. This makes it an excellent niche for high-margin carving work that remains stable during economic downturns.

Custom Headstones & Tombstones with 3D Reliefs

- Profit Potential: High. Families willingly pay premiums for unique memorials. Adding 3D-carved elements like praying hands or floral motifs can double standard headstone prices.

- Target Market: Funeral homes, memorial parks, direct to families.

- Two-Machine Workflow: CNC Diamond Wire Saw Machine for Natural Stone Tombstones for shapes and batch cutting, CNC Stone Engraving Machine for lettering and 3D reliefs.

Engraved Memorial Plaques & Garden Stones

- Profit Potential: Medium. Smaller, lower-cost items but can be produced quickly and in volume. Great entry point into the memorial market.

- Target Market: Pet owners, landscape designers, gift shops.

- Equipment Needed: Small-format CNC Stone Engraving Machine for 3D Relief & Tombstones with high-quality diamond carving bit for crisp lettering.

Religious Statuary & Sculptures

- Profit Potential: High. Churches, temples, and religious institutions commission life-sized or smaller statues. These are complex, high-value art pieces.

- Target Market: Religious organizations, private collectors, community groups.

- Advanced Requirements: 7-Axis Robotic Arm for 3D Stone Carving & Cutting for full 3D capabilities needed for human figures and complex shapes with intricate details and undercuts.

Niche & Creative Applications: Specialized Market Opportunities

These projects cater to specific commercial or creative markets. They allow you to become the go-to specialist in unique areas with less competition and higher profit margins.

Stone Bar & Restaurant Counter Fronts

- Profit Potential: High. Custom-carved bar fronts with logos or intricate patterns create unforgettable atmospheres and serve as major selling points for high-end hospitality venues.

- Target Market: Restaurant and hotel designers, bar owners, commercial contractors.

- Large-Format Requirements: 5-Axis CNC Bridge Saw handles the scale and 3D carving for impressive installations.

Landscape & Garden Sculptures

- Profit Potential: Medium to High. Abstract sculptures, stone benches, and custom water features are in demand for high-end gardens and public parks.

- Target Market: Landscape architects, municipalities, luxury homeowners.

- Flexible Workflow: Pro CNC Wire Saw for main profiles, CNC Stone Engraving Machine for surface details, CNC Stone Lathe for cylindrical elements.

Custom Stone Mosaics

- Profit Potential: Medium. Labor-intensive if done by hand, but highly profitable when using CNC to cut individual tesserae. Enables complex, photorealistic designs.

- Target Market: Artists, interior designers, tile suppliers.

- Precision Cutting: 5-Axis CNC Waterjet for Precision Stone & Metal Cutting cuts intricate shapes from different colored stones without heat-affected zones or chipping.

Stone Awards & Trophies

- Profit Potential: Medium. Corporate awards provide recurring business. Custom stone trophies have much higher perceived value than standard glass or acrylic alternatives.

- Target Market: Corporations, event organizers, non-profit organizations.

- High Precision Needed: Smaller CNC Stone Engraving Machine with high precision for detailed engraving and shaping.

Choosing the Right Machine for High-Margin Carving

Investing in the right CNC machine represents the single most important factor for success in high-margin carving. The wrong machine limits creative potential, while the right one becomes a reliable profit engine.

For comprehensive technical guidance, explore The Complete Guide to CNC Stone Carving

3-Axis vs. 5-Axis vs. Robotic Arms: What's the Real ROI?

3-Axis Systems

Excellent for 2.5D work like engraving, lettering, and simple reliefs (plaques, basic logos). Lower initial cost but creatively limited.

- Best for: Entry-level operations

5-Axis Systems

The profitability sweet spot. Handles complex 3D shapes, undercuts, and intricate details (fireplaces, corbels, sinks). Higher investment quickly justified by project values.

- Best for: Established businesses scaling up

Robotic Arms

Ultimate flexibility. Required for true 3D sculptures, parametric furniture, and large complex forms. Highest investment but opens markets with minimal competition.

- Best for: Premium art and sculpture markets

Key Machine Specs to Look For: Spindle Power, Gantry Clearance, and Precision

Look beyond axis count when choosing machines. A heavy, rigid frame made from cast iron (like DINOSAW machines) is crucial for dampening vibration and ensuring flawless finishes.

High-precision ball screws and servo motors are non-negotiable for accuracy demanded by high-margin work. Ensure adequate gantry clearance (Z-axis height) for thick blocks used in carving applications.

Software & Tooling: The Hidden Keys to Profitability

Your CNC machine performs only as well as the software driving it and the bits doing the cutting. Invest in robust CAD/CAM software (like RhinoCAM, AlphaCAM) capable of handling complex 3D models.

Don't compromise on tooling quality. High-quality diamond bits reduce chipping, improve surface finish, and lower overall operational costs. The initial investment pays dividends in reduced rework and superior results.

Pricing Your Work & Finding Your First High-Ticket Client

Transitioning to high-margin work requires a fundamental mindset shift. Move from quoting per square foot to pricing based on value, artistry, and machine time.

Pricing Models: Per-Hour vs. Per-Project

Per-Hour Pricing

Calculate your machine's hourly operational cost (including labor, electricity, tooling, and machine amortization). Add a healthy profit margin of 100-300% as your starting point.

Per-Project Pricing

For larger, complex projects, fixed pricing works better. Base estimates on design time, machine programming, run time, material cost, and finishing labor, plus value-based markup for uniqueness and artistry.

Building a Portfolio to Attract Designers and Architects

You don't need existing clients to start. Purchase several interesting stone blocks and create 2-3 stunning portfolio pieces. Professional photography of these pieces becomes your most powerful marketing tool for attracting high-end clients.

According to the Natural Stone Institute , showcasing finished projects is the most effective way to communicate the beauty and value of natural stone to potential customers.

Frequently Asked Questions (FAQs)

What is the most profitable type of stone to carve?

The most profitable stones combine high perceived value with good workability, such as Carrara Marble, Travertine, and high-quality Granite. Profitability depends more on the value you add through intricate design and craftsmanship than the stone type itself. Marble is preferred for interior art due to its classic appeal, while granite is essential for durable outdoor and memorial projects.

How much does a professional CNC stone carving machine cost?

Professional CNC stone carving machines range from $30,000 for basic 3-axis models to over $200,000 for advanced 5-axis or robotic systems. Price depends on size, axis configuration, spindle power, and brand. While the initial investment seems substantial, a reliable machine like a DINOSAW 5-axis model can achieve ROI within 12-24 months through high-margin projects.

Can I start a stone carving business from my garage?

Starting from a small workshop is possible with key considerations. You need a solid, level concrete foundation to handle machine weight and vibration, adequate power supply (often 3-phase), and space for material handling. A smaller 3-axis machine for projects like plaques and awards is more feasible for garage setups than large machines for architectural pieces.

What is the hardest part of CNC stone carving?

The most challenging part is often the "pre-carving" stage: creating accurate 3D models and generating flawless toolpaths in your CAM software. The carving itself is automated, but programming requires skill. Garbage in, garbage out. Investing in good software and training is crucial to prevent costly errors and material waste. DINOSAW provides comprehensive training and support to help clients master this process.

How do I prevent tool wear and chipping on hard granite?

Preventing premature tool wear and chipping on granite requires three things: 1) Using correct diamond tooling designed specifically for hard stone. 2) Optimizing feeds and speeds in CAM software - running too fast or too deep destroys bits. 3) Using ample coolant to reduce heat and clear dust. A machine with rigid structure is vital, as vibration is a primary cause of microchipping.

What is the market outlook for custom architectural stone?

The market outlook is strong, particularly in the luxury building sector. According to reports from European trade bodies like VDMA , demand for high-end, customized building materials continues growing. Architects are specifying unique stone elements to differentiate their projects, ensuring steady demand for fabricators with advanced CNC carving capabilities.

English

English 中文

中文