Hi, this is Lizzy from Dinosaw ( Not a Robot ). Which Machine ( model ) do you want? Please WhatsApp us now

Professional rock cutting machine selection guide. Technical specifications, OSHA safety compliance, CNC systems, and B2B procurement for industrial stone processing.

Industrial rock cutting machines boost production efficiency in commercial stone processing. They deliver precision control, automated operation, and integrated safety systems. Professional operations need equipment meeting regulatory standards while maintaining consistent quality and operational reliability across diverse stone materials.

Three factors determine rock cutting machine success. First, material hardness matching via Mohs scale assessment. Second, diamond blade specification for target materials. Third, integrated dust collection for safety compliance. Professional systems combine these elements with CNC automation for optimal throughput and quality consistency.

This guide covers essential technical specifications, safety requirements, and operational protocols. You'll find equipment selection criteria for B2B procurement and industrial stone processing applications.

Industrial Rock Cutting Machine Categories & Technical Specifications

Block Processing & Primary Cutting Systems

Industrial block processing forms the foundation of commercial stone operations. Multi-blade cutting systems deliver precision, efficiency, and reliability across granite, marble, sandstone, and specialized materials. They provide proven commercial performance that industrial operations depend on.

Primary Block Cutting Technologies

- Heavy-Duty Stone Block Cutting Machines: Multi-blade systems with 55kW motors achieving 450㎡/day production capacity and ±0.2mm cutting precision through hydraulic control systems

- Single Column Auto Cutting Machines: Automated cutting systems with PLC controls for granite, marble processing with multiple blade configurations and variable speed systems

- Block Squaring Diamond Wire Saws: Precision dimensional control systems delivering minimal kerf loss for downstream processing optimization

- Horizontal Blade Stone Block Cutters: Large block processing systems optimized for enhanced stability and cutting accuracy in commercial operations

- Single Blade Bridge Saws: Optimized configurations for high-precision straight cuts and block sizing operations

Commercial block processing requires matching equipment capacity to production requirements. Modern systems feature cast bridge construction, large-diameter guide columns, and permanent magnet motor technology. These deliver 20% energy savings while maintaining industrial-grade precision for high-volume operations.

Advanced CNC Bridge Saws: Precision Cutting & Complex Geometries

CNC bridge saw technology transforms precision stone processing through programmable control and automated operation. These systems deliver exceptional accuracy that manual methods simply can't match. Modern bridge saw systems handle everything from simple cuts to complex architectural elements.

CNC Bridge Saw Capabilities

- Professional CNC Bridge Saws: Advanced servo control systems achieving ±0.1mm precision for countertop and architectural applications

- 5-Axis CNC Saws: Multi-axis cutting capabilities enabling complex undermount cutouts with seamless edge finishing

- 4+1 Axis CNC Saws: High-power spindle motors (22kW) with 0-24,000 rpm variable speed for sink processing

Professional CNC systems integrate automated material handling with programmable cutting sequences. They include real-time quality monitoring that catches issues before they become problems. Advanced spindle technology with water cooling prevents thermal damage. This maintains consistent surface quality across diverse materials from soft limestone to hard quartzite.

Diamond Wire Saw Technology: Ultra-Thin Cutting & Maximum Yield

Diamond wire saw technology represents a breakthrough in material utilization and cutting precision. Wire saw systems deliver exceptional yield improvements through ultra-thin kerf cutting. Advanced tension control systems ensure consistent performance across different materials.

Wire Saw Technology Applications

- Multi-Wire Saw Machines: Ultra-thin slab cutting achieving 3mm cutting capability with 35% material waste reduction compared to traditional gang saws

- CNC Diamond Wire Saws: Irregular cutting systems with ±1mm precision and 360° rotating capability for complex geometries

- Quarry Diamond Wire Saws: Industrial extraction systems for primary cutting with superior material yield and reduced fracturing

Wire saw technology delivers measurable ROI through enhanced material utilization. Industry case studies demonstrate yield improvements of 20-26% on premium materials . This generates additional revenue through enhanced material recovery and reduced waste disposal costs.

Specialized Infrastructure & Quarrying Solutions

Infrastructure stone processing demands specialized equipment capable of high-volume production with dimensional consistency. Municipal projects need reliable systems that can handle thousands of linear feet. Specialized systems address quarrying, curbstone production, and architectural stone processing requirements.

Infrastructure Processing Systems

- Automated Curbstone Cutting Lines: Complete production systems with ±0.5mm tolerances for municipal infrastructure projects

- Sandstone Cutting Machines: Specialized quarrying equipment optimized for efficient extraction and processing

- Double Blade Quarrying Machines: Twin-blade systems for enhanced productivity in block extraction operations

- Gantry Block Cutting Saws: Heavy-duty equipment for large-scale industrial cutting with exceptional structural rigidity

Municipal projects benefit from automated curbstone production. These systems deliver consistent dimensional accuracy across thousands of linear feet. Specialized quarrying equipment maximizes block yield while minimizing extraction costs. This happens through optimized cutting patterns and reduced material waste.

Advanced Processing: Waterjet, Profiling & Finishing Systems

Advanced stone processing requires specialized technologies for complex geometries and precision finishing. Standard cutting methods can't handle specialized materials or intricate shapes. Advanced systems deliver capabilities that go far beyond traditional cutting methods.

Advanced Processing Technologies

- 5-Axis CNC Waterjet: Precision cutting systems with ±0.1mm accuracy and cold cutting capability

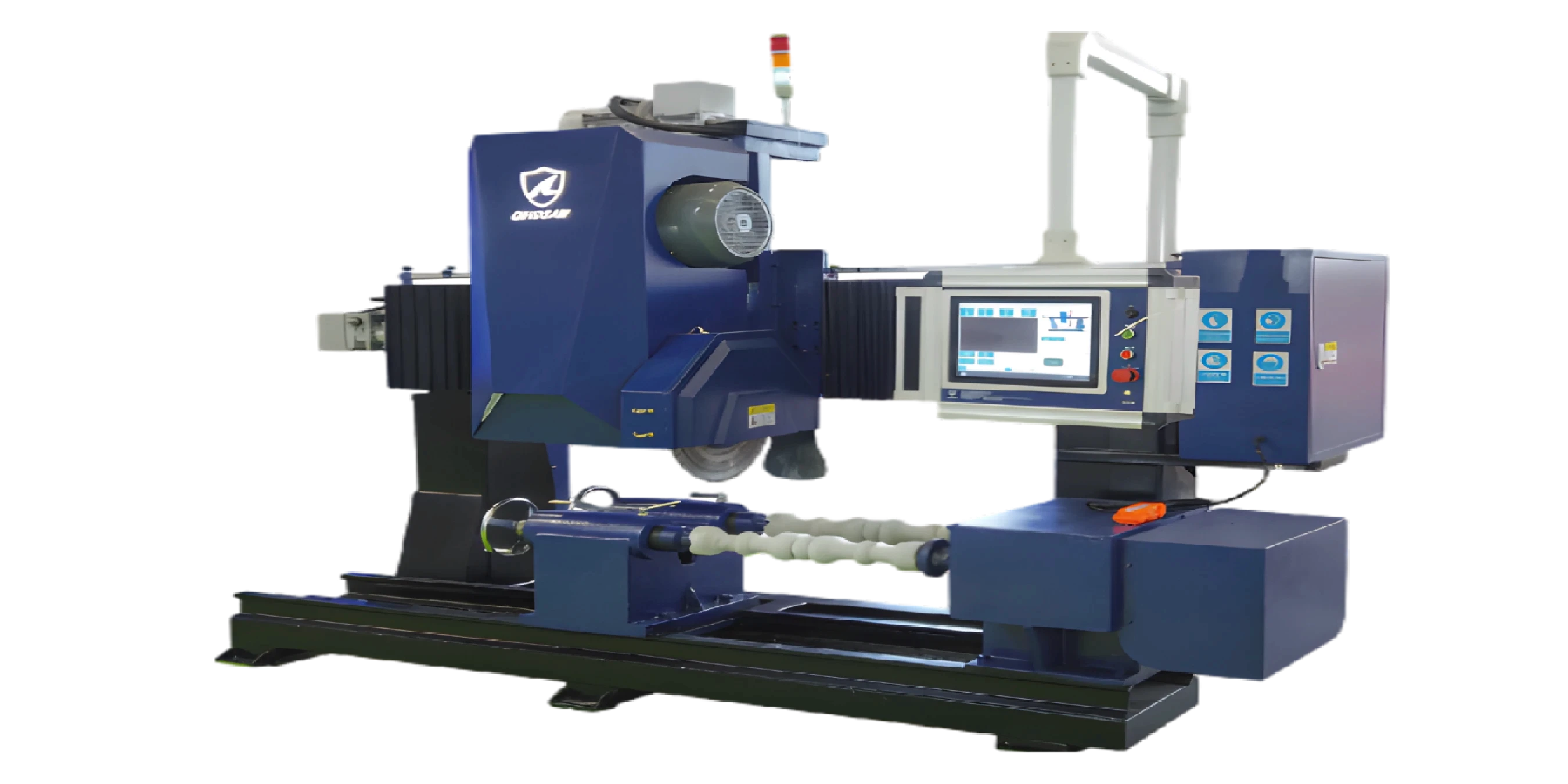

- CNC Stone Lathes: Architectural column processing for balustrades, columns, and decorative elements

- CNC Stone Profiling Machine: Complex edge profiles and custom shape processing systems

- Arc Slab Trimming Machine: Curved cutting systems for specialized applications

Waterjet technology excels in processing heat-sensitive materials and complex geometries that traditional methods can't handle. Five-axis motion capabilities enable undermount sink cutouts, curved transitions, and intricate decorative elements. All with exceptional precision that meets the tightest tolerances.

Industrial & Manual Systems: Versatile Processing Solutions

Diverse operational requirements demand flexible equipment solutions. Industrial operations need different capabilities than small-scale specialty work. DINOSAW's industrial and manual systems provide scalable options from small-scale operations to heavy industrial applications.

Industrial & Manual Processing Range

- Vertical 4-Pillars Stone Cutting Machine: Vertical cutting system for baluster and column processing with enhanced stability

- Manual Industrial Stone Cutting Machine: Manual industrial cutter providing cost-effective solutions for skilled operators

- Stone Splitting Machine: Splitting system for specialized applications

Manual systems provide flexibility for specialized applications and skilled craftwork. Industrial systems deliver consistent performance for high-volume production. Each system integrates safety features and ergonomic design. This ensures optimal operator performance and regulatory compliance.

Safety Compliance & Operational Protocols

OSHA Crystalline Silica Standards for Industrial Operations

⚠️ Mandatory Compliance Requirements

OSHA standard 29 CFR 1926.1153 mandates exposure limits below 50 micrograms per cubic meter for crystalline silica. Industrial rock cutting operations require integrated dust collection, water suppression, and continuous air monitoring systems.

Required Safety Systems

- Engineering Controls: Enclosed cutting chambers, automated water suppression

- Dust Collection: HEPA filtration, continuous monitoring, automated reporting

- Water Systems: Recirculation, filtration, temperature control

- Documentation: Exposure tracking, training records, compliance reporting

Operational Setup & Quality Control

Standard Operating Procedure

- Material Assessment: Hardness verification, inclusion mapping, cutting sequence planning

- Machine Setup: Blade selection, speed/feed calibration, coolant system check

- Safety Verification: PPE confirmation, ventilation systems, emergency procedures

- Test Cuts: Parameter validation, quality assessment, adjustment protocol

- Production Run: Continuous monitoring, quality sampling, documentation

Quality Control Standards

- Dimensional Accuracy: ±0.1mm for CNC systems, ±0.5mm for standard equipment

- Surface Finish: Ra 0.8-3.2 μm depending on application requirements

- Edge Quality: No chipping >0.5mm, consistent geometry profiles

- Material Integrity: Check for internal stress or damage patterns

💬 Industrial Equipment Consultation

Need technical guidance on rock cutting machine selection or exploring dealer partnerships? Our industrial specialists provide equipment evaluation, facility planning, and B2B program details.

Common Issues & Professional Solutions

| Issue | Root Cause | Solution |

|---|---|---|

| Blade Jamming | Excessive feed rate, material binding | Reduce pressure, check alignment, replace blade |

| Poor Cut Quality | Wrong blade spec, incorrect parameters | Match blade to material, optimize speed/feed |

| Motor Overheating | Insufficient cooling, overload | Increase coolant flow, reduce load |

| Water System Issues | Clogged filters, pump failure | Clean filters, service pump, replace coolant |

| Excessive Vibration | Unbalanced blade, worn bearings | Balance/replace blade, service bearings |

Supplier Evaluation & B2B Partnerships

Professional Equipment Procurement Criteria

Supplier Assessment Framework

- Technical Capability: Engineering support, application expertise, custom solutions

- Service Infrastructure: Local support, parts availability, training programs

- Quality Systems: Manufacturing standards, testing protocols, warranty coverage

- Market Position: Financial stability, innovation track record, customer references

Professional equipment evaluation requires comprehensive assessment of technical capability and service infrastructure. You need to evaluate quality systems and market position too. Supplier selection criteria should include engineering support, local service availability, and manufacturing standards. Long-term stability matters for successful B2B partnerships.

Dealer Partnership Benefits

- Territory Protection: Exclusive regional rights, competitive pricing structure

- Technical Training: Certification programs, ongoing education, application support

- Marketing Support: Co-marketing programs, demonstration equipment, customer referrals

- Service Backing: Technical support, warranty administration, parts logistics

DINOSAW Industrial Stone Processing Solutions

Comprehensive Equipment Portfolio

DINOSAW delivers comprehensive stone processing solutions covering cutting, slicing, sawing, and processing requirements. We serve 75+ countries with 20+ years of industry expertise. Our integrated product line addresses the complete stone processing workflow from quarrying to finished products.

Our equipment serves traditional industries like mining, stone processing, and building materials. We also handle high-precision manufacturing for quartz glass and semiconductor applications. Specialized applications include infrastructure and architectural elements with proven performance and comprehensive support.

Frequently Asked Questions

What OSHA compliance is required for commercial rock cutting operations?

Commercial operations must implement comprehensive engineering controls per OSHA 29 CFR 1926.1153. Requirements include integrated dust collection, water suppression systems, and continuous air monitoring. You need enclosed cutting environments too. Exposure limits below 50 micrograms per cubic meter mandate documented compliance programs. These include operator certification and emergency procedures.

How do CNC rock cutting systems improve industrial operations?

CNC systems deliver ±0.1mm precision with 24/7 operational capability and minimal supervision. Automated control eliminates operator variability and enhances material utilization through nesting optimization. They provide consistent quality that manual operations can't match. ROI typically realizes within 12-18 months through productivity improvements and reduced labor costs in high-volume applications.

What production capacity can industrial rock cutting machines achieve?

Production capacity varies by system type and material properties. Commercial slab saws with 12-18 inch blades process 100-200 square feet per hour on medium-hardness materials. Industrial CNC systems achieve 150-500 square feet per hour with automated feeding. Multi-blade automated lines exceed 500 square feet per hour through continuous operation.

What dealer partnership programs are available for rock cutting equipment?

Comprehensive dealer programs include territory protection, technical training, and marketing support. Benefits include competitive wholesale pricing, exclusive regional rights, and product certification programs. You get ongoing technical support too. Requirements include minimum order commitments, certified technical staff, and customer service capabilities for industrial market development.

How do I select the right diamond blade for rock cutting applications?

Diamond blade selection requires matching mesh size, bond matrix, and rim configuration to material hardness. Use 60 mesh for fast cutting, 200-400 mesh for balanced performance, and 3 microns for precision finishing. Soft bonds work with hard materials (Mohs 7-10), hard bonds with soft materials (Mohs 1-6). Continuous rims provide smooth cuts, segmented rims enable fast cutting.

What maintenance protocols extend rock cutting machine performance?

Preventive maintenance programs significantly impact equipment reliability and operational costs. Daily protocols include coolant level checks and safety system verification. Weekly maintenance covers lubrication and belt tension. Monthly service includes bearing inspection and filter replacement. Quarterly overhauls with professional inspection extend equipment life 200-400% while maintaining regulatory compliance.

English

English 中文

中文